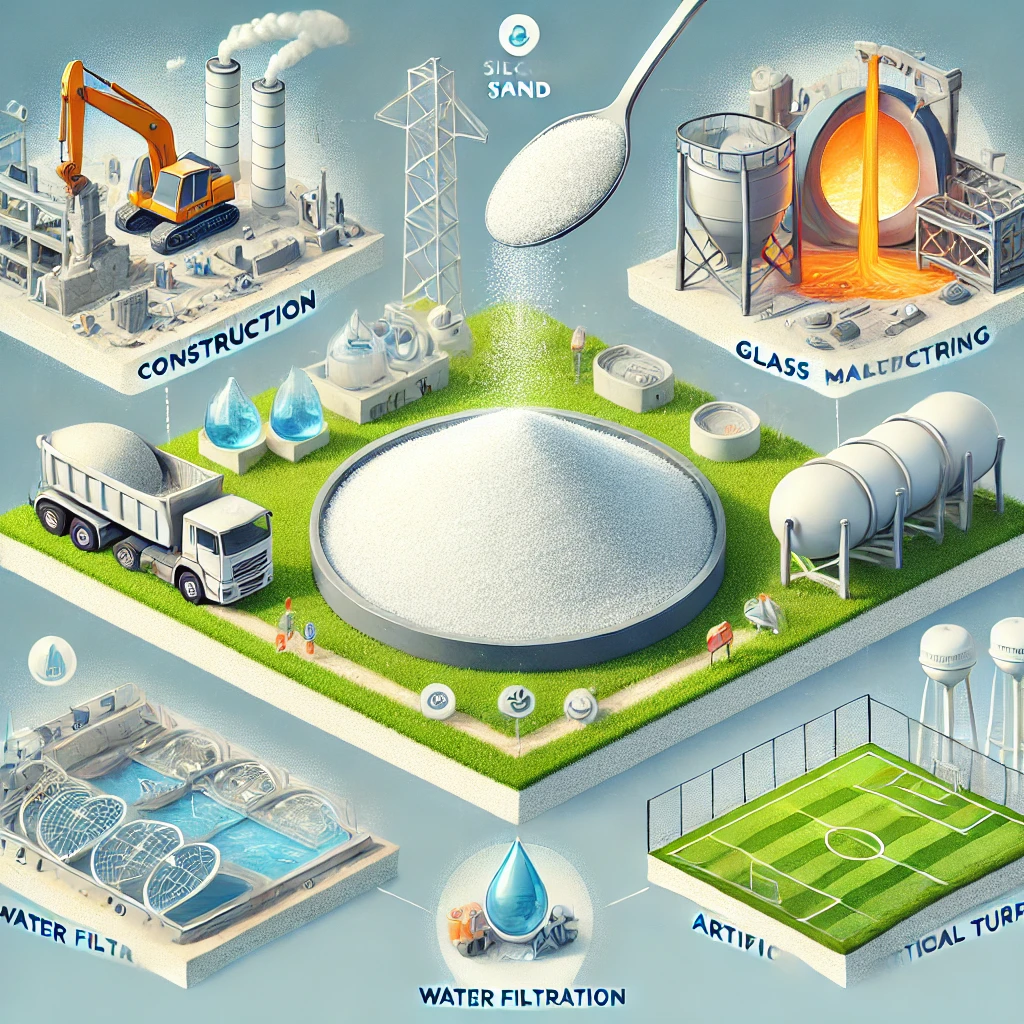

Silica sand is a versatile material used across various industries, from construction to manufacturing and filtration. One of its most important characteristics is its particle size, which directly impacts its performance in different applications. In this article, we’ll explore the significance of silica sand size, typical size classifications, and how to choose the right size for your needs.

Why Silica Sand Size Matters

The particle size of silica sand determines its functionality in specific applications. Smaller particles provide greater surface area and are ideal for filtration and glassmaking, while larger grains are preferred in construction and foundry work. Key factors influenced by silica sand size include:

- Filtration Efficiency: Smaller grains are better at trapping impurities.

- Strength and Durability: Coarser sand adds strength to concrete and mortar.

- Thermal Properties: Uniform grain sizes improve thermal conductivity in foundries.

Silica Sand Size Chart

Silica sand is categorized by its particle size, typically measured in mesh size or microns. Below is a general silica sand size chart:

| Mesh Size | Particle Diameter (Microns) | Particle Diameter (mm) | Common Applications |

|---|

| 4-8 Mesh | 2380-4760 µm | 2.38-4.76 mm | Sandblasting, landscaping |

| 8-16 Mesh | 1190-2380 µm | 1.19-2.38 mm | Foundry molds, construction materials |

| 16-30 Mesh | 595-1190 µm | 0.595-1.19 mm | Pool filtration, concrete additives |

| 30-50 Mesh | 297-595 µm | 0.297-0.595 mm | Glassmaking, water filtration |

| 50-100 Mesh | 149-297 µm | 0.149-0.297 mm | Paint fillers, industrial coatings |

| 100-200 Mesh | 74-149 µm | 0.074-0.149 mm | Specialty coatings, fine glass |

| 200+ Mesh | <74 µm | <0.074 mm | Precision glass, electronics |

Note: The exact size distribution can vary depending on the supplier and intended use.

Applications by Particle Size

- Coarse Grains (4-16 Mesh):

- Applications: Landscaping, road construction, and foundries.

- Advantages: Excellent for adding texture and structural integrity.

- Medium Grains (16-50 Mesh):

- Applications: Glass manufacturing, pool filtration, and mortar.

- Advantages: Provides uniformity and high-quality finishes.

- Fine Grains (50-200+ Mesh):

- Applications: Precision glass, industrial coatings, and chemical production.

- Advantages: Ideal for detailed, high-performance applications.

How to Choose the Right Silica Sand Size

When selecting silica sand, consider the following:

- Industry Requirements: Match the particle size with your application needs.

- Purity Levels: Ensure the sand meets industry standards for contaminants.

- Supplier Specifications: Request a detailed size distribution chart.

Importance of Uniform Grain Size

Uniformity in silica sand grain size ensures consistency in performance. For example:

- In Glassmaking: Uniform sand ensures a smooth finish and clarity.

- In Filtration: Consistent grain sizes prevent clogging and improve filtration rates.

Conclusion

Understanding the silica sand size chart and its applications is essential for optimizing its performance in your projects. From coarse grains for construction to fine particles for specialty glass, choosing the right size ensures efficiency and cost-effectiveness.

If you’re looking for high-quality silica sand tailored to your specific needs, explore our silica sand products or contact us for expert guidance.