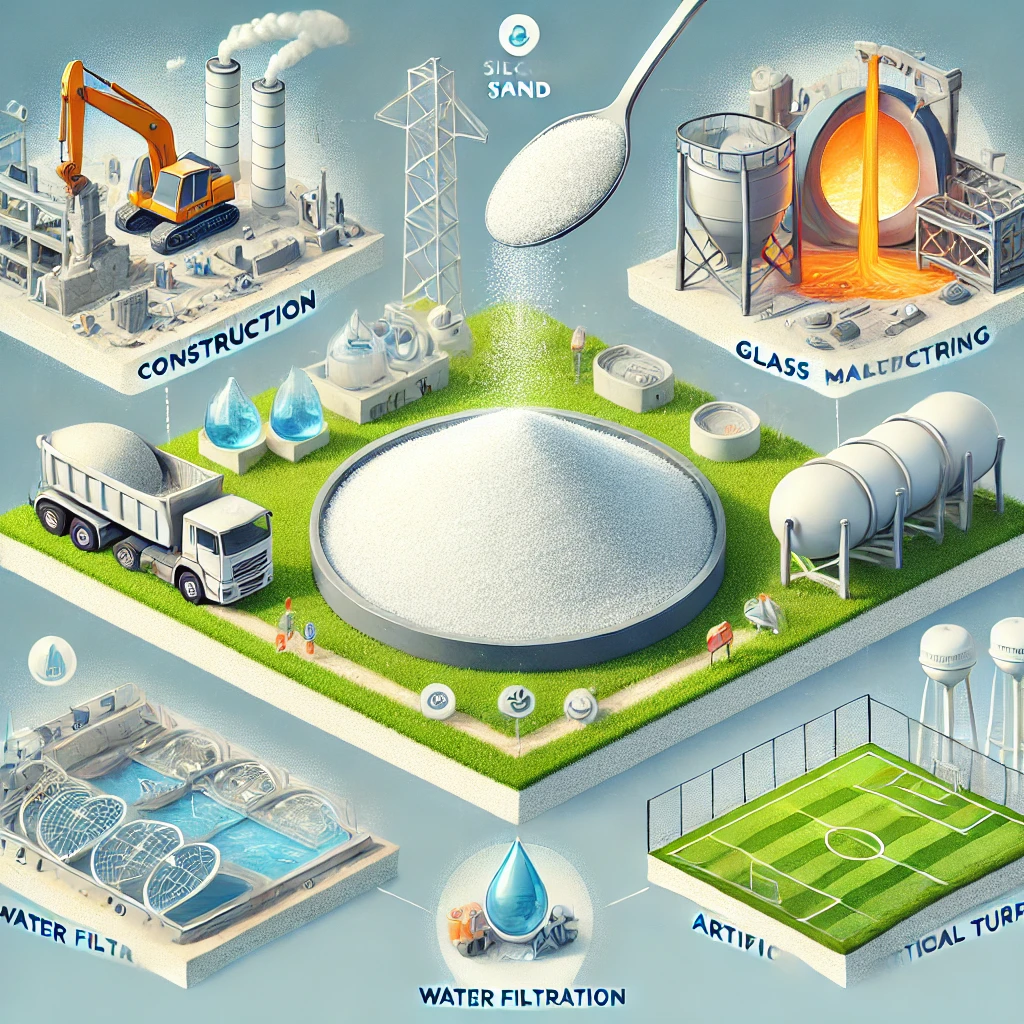

In industrial settings, water treatment is a crucial process that ensures the removal of impurities to meet operational and environmental standards. We widely use silica sand as a filtration medium in industrial water treatment systems due to its efficiency, durability, and cost-effectiveness. This guide explores how we use silica sand in industrial water treatment and why it is an essential component in maintaining clean water systems.

Why Use Silica Sand in Industrial Water Treatment?

Silica sand offers several advantages that make it an ideal choice for industrial water filtration:

- High Filtration Efficiency: Its porous structure and consistent grain size enable effective removal of particles and impurities.

- Durability: Resistant to wear, silica sand maintains its performance even under high-pressure and high-volume conditions.

- Chemical Stability: As an inert material, silica sand does not react with chemicals used in water treatment processes.

- Affordability: Compared to other filtration media, silica sand is cost-effective and widely available.

Applications of Silica Sand in Industrial Water Treatment

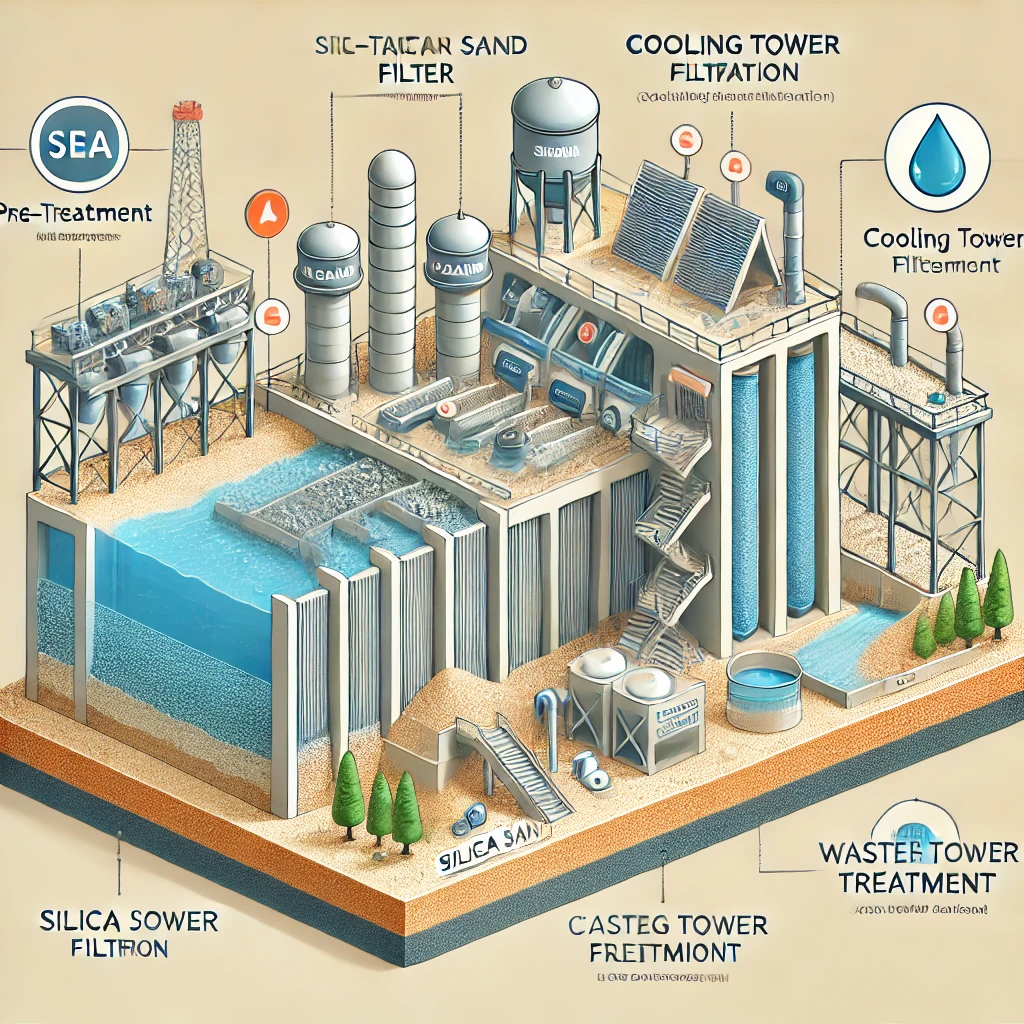

1. Pre-Treatment Filtration

Silica sand is used to filter out larger particles and debris before the water enters advanced treatment stages. This protects downstream equipment and improves overall system efficiency.

2. Cooling Tower Water Filtration

Industrial cooling towers often require filtration to remove suspended solids and contaminants that can lead to scaling, corrosion, and biofouling. Silica sand ensures clean water circulation, enhancing the efficiency and lifespan of cooling systems.

3. Wastewater Treatment

In industrial wastewater treatment, silica sand is utilized to separate solids from liquids, making it easier to meet discharge regulations and prepare water for reuse or safe disposal.

4. Desalination Plants

Silica sand acts as a pre-treatment filter in desalination plants, removing sediment and particulates before water undergoes reverse osmosis or distillation.

How to Use Silica Sand in Industrial Water Treatment

1. Layer Configuration

In most filtration systems, silica sand is layered with other media such as anthracite or gravel. The layers are arranged based on particle size, with coarser materials at the bottom and finer materials at the top.

2. Backwashing

Periodic backwashing is necessary to clean the silica sand bed and remove trapped particles. This process involves reversing the flow of water to flush out impurities.

3. Replacement

Over time, silica sand may lose its angularity and become less effective. Regular monitoring and timely replacement ensure continued filtration efficiency.

Advantages of Using Silica Sand

- Versatility: Suitable for various industrial applications, from cooling systems to wastewater treatment.

- Eco-Friendly: As a natural material, silica sand is sustainable and can often be recycled.

- Low Operational Costs: Its durability and efficiency reduce maintenance and replacement expenses.

Selecting the Right Silica Sand

When choosing silica sand for industrial water treatment, consider:

- Purity: High-purity silica sand ensures better filtration and minimal impurities.

- Grain Size: The size should match the specific requirements of the filtration system.

- Supplier Reliability: Choose suppliers with proven quality and certifications.

Conclusion

Silica sand is an indispensable component in industrial water treatment, offering unmatched efficiency and reliability. Whether it’s pre-treatment, cooling tower filtration, or wastewater management, silica sand ensures clean and compliant water systems for industrial operations.

If you’re looking for high-quality silica sand tailored to your industrial water treatment needs, contact us today. Our premium-grade silica sand meets the highest standards for performance and durability.