Silica Sand: Properties, Uses, and Applications

Silica sand, also known as quartz sand, is a versatile material that plays a vital role in various industries. From construction and manufacturing to filtration and energy production, silica sand’s unique properties make it a cornerstone of modern industrial processes. In this article, we’ll explore what silica sand is, its properties, primary uses, and why it’s a primary material in today’s world.

What is Silica Sand?

Silica sand is a naturally occurring material composed primarily of silicon dioxide (SiO₂). Found in quartz-rich deposits worldwide, it is one of the most abundant and versatile minerals on Earth. Its high purity and unique properties make it suitable for various industrial applications.

Key Properties of Silica Sand

Silica sand’s properties determine its applications across industries. These include:

- Purity: High-purity silica sand contains up to 99.5% silicon dioxide, ensuring consistency and effectiveness in specialized uses.

- Grain Size: The sand grains range from fine to coarse, with different sizes catering to specific applications.

- Hardness: With a Mohs hardness of 7, silica sand is highly durable.

- Chemical Stability: It resists chemical reactions, making it ideal for industrial and construction applications.

- Transparency: Used in glass manufacturing for its clarity and transparency.

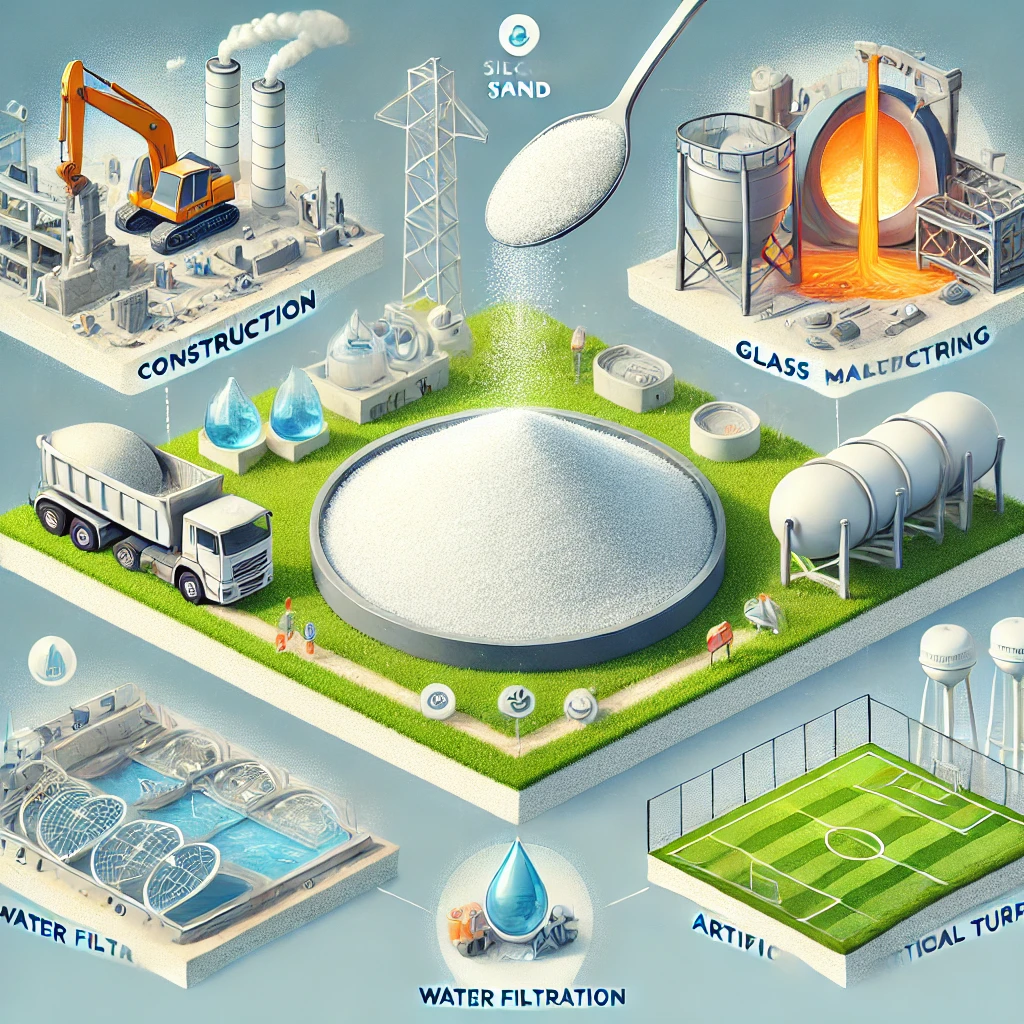

Major Uses of Silica Sand

Silica sand is essential in various sectors, including:

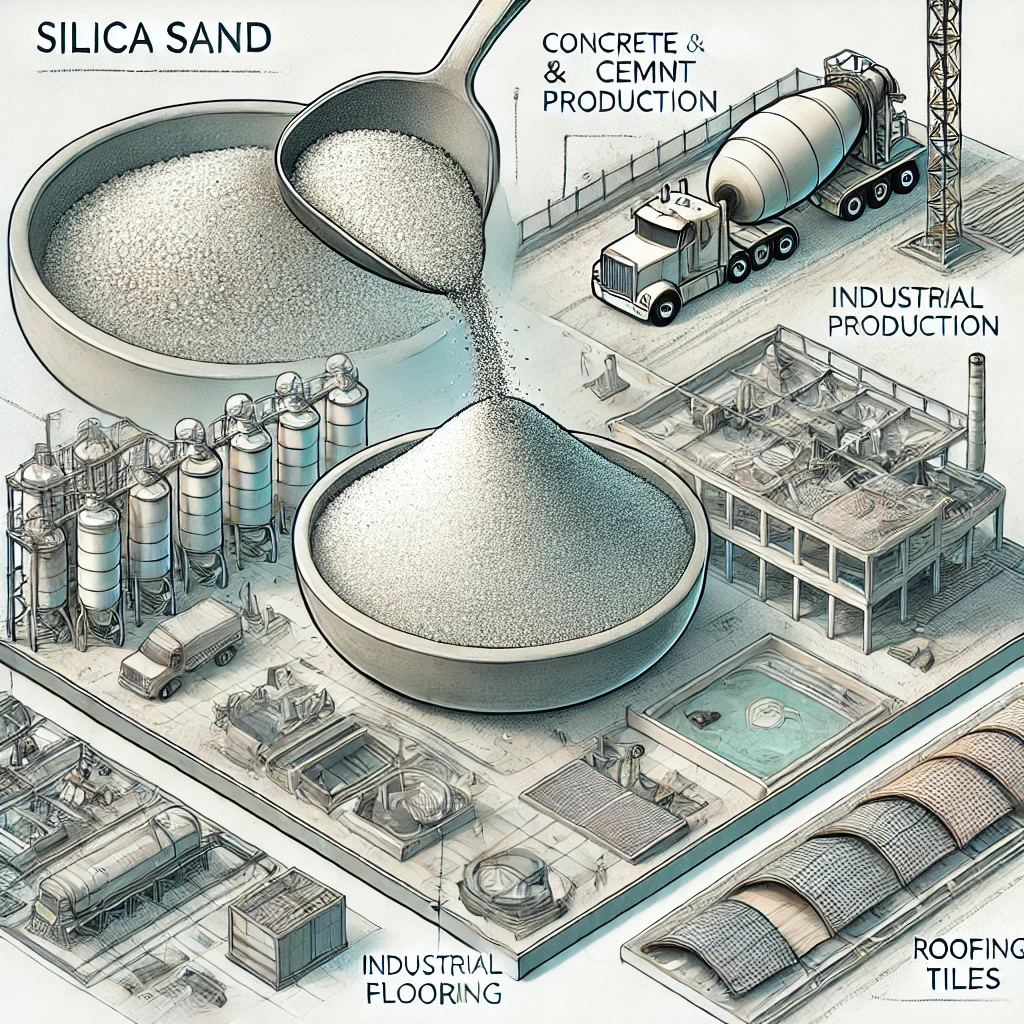

- Construction

- Used as a primary ingredient in concrete, cement, and mortar.

- Serves as a key material in industrial flooring, roofing tiles, and grouting.

- Glass Manufacturing

- Silica sand is the main raw material in producing clear and colored glass for windows, bottles, and optical instruments.

- Water Filtration

- Acts as a filtration medium to remove impurities in municipal and industrial water treatment plants.

- Foundry and Casting

- Used in molds and cores for casting metals due to its high melting point and durability.

- Energy Sector

- Plays a role in hydraulic fracturing (fracking) to extract oil and natural gas from rock formations.

- Electronics

- High-purity silica sand is used in the production of silicon wafers for semiconductors and solar panels.

Benefits of Silica Sand

- Sustainability: Silica sand is a renewable resource when managed responsibly.

- Cost-Effectiveness: It is widely available and affordable compared to alternatives.

- Versatility: Suitable for applications across a broad range of industries.

- Durability: High resistance to wear and tear, ensuring longevity in industrial uses.

Sourcing High-Quality Silica Sand

Finding reliable suppliers is crucial for ensuring consistent quality and supply. Factors to consider include:

- Purity levels.

- Grain size distribution.

- Certifications and compliance with industry standards.

In Saudi Arabia, companies like Gharbalah Industrial Company specialize in high-quality silica sand production, ensuring it meets diverse industrial needs.

FAQs About Silica Sand

- What is silica sand used for?

- Silica sand is used in construction, glass manufacturing, water filtration, foundry casting, and more.

- What makes silica sand different from regular sand?

- Silica sand contains a higher concentration of silicon dioxide, offering superior purity and specific properties for industrial applications.

- Is silica sand environmentally friendly?

- Yes, it is a natural resource and can be managed sustainably for minimal environmental impact.

Conclusion

Silica sand is a critical material that supports numerous industries worldwide. Its unique properties, versatility, and availability make it indispensable in construction, glass production, energy, and beyond. Whether you’re seeking detailed information or high-quality silica sand for your business, having access to reliable resources and suppliers ensures success in your endeavors.

For more information on silica sand or to source premium-grade materials, explore our website or contact us today!