Silica Sand in Glass Manufacturing: Essential Properties and Applications

Silica sand, a high-purity form of quartz, is the cornerstone of glass manufacturing. Known for its exceptional clarity, chemical stability, and heat resistance, silica sand is the primary raw material used in creating glass products for a wide range of applications. In this article, we’ll explore how silica sand contributes to glassmaking process, its benefits, and it is essential in various industries.

What is Silica Sand?

Silica sand is a natural material composed predominantly of silicon dioxide (SiO₂). Its purity and particle size make it ideal for glass production. When combined with other raw materials, silica sand transforms into glass through high-temperature melting and cooling process.

Key Properties of Silica Sand for Glass Manufacturing

Silica sand’s unique properties make it indispensable in glass production:

- High Purity: Typically, silica sand used in glass contains over 99% silicon dioxide, ensuring clarity and strength.

- Grain Size Uniformity: Facilitates consistent melting during glass production.

- Low Iron Content: Minimizes impurities and enhances transparency, especially in clear and optical glass.

- Heat Resistance: Withstands high temperatures without degrading.

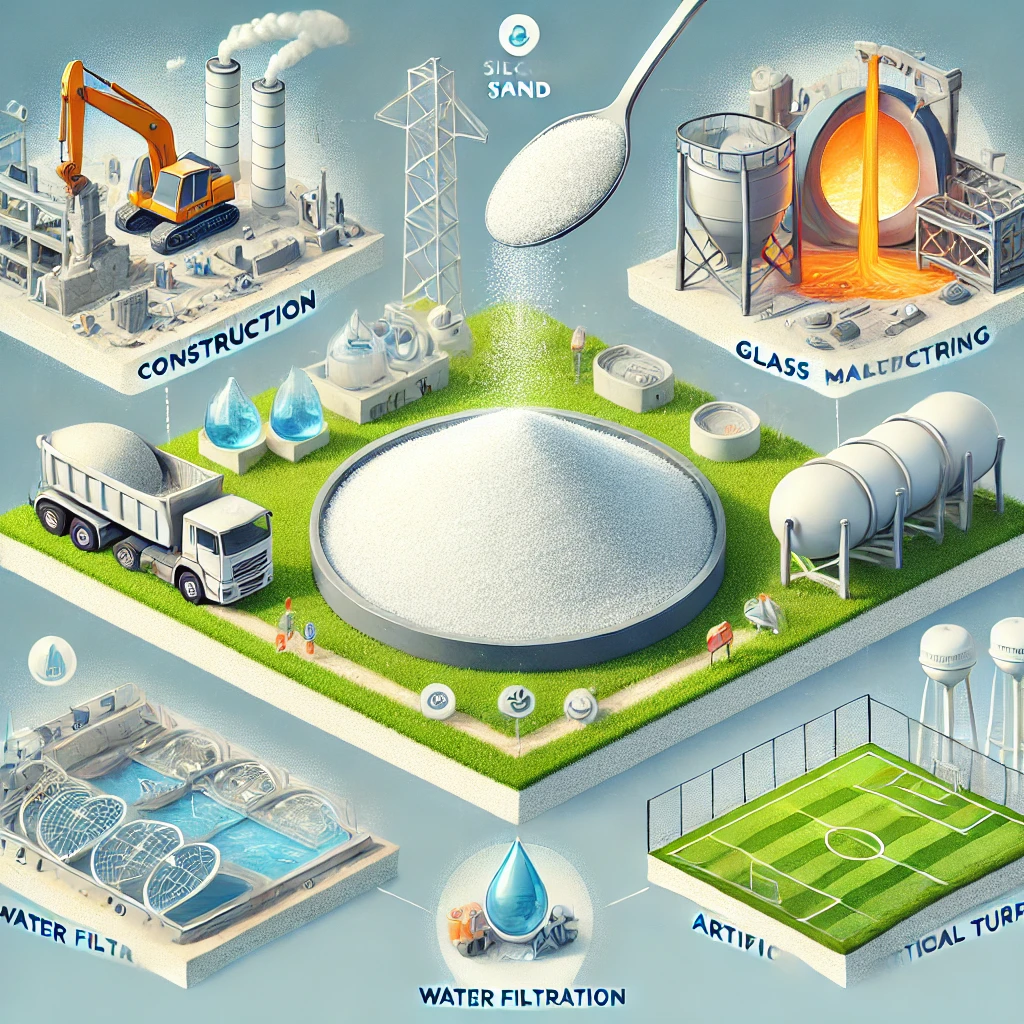

Applications of Silica Sand in Glass Manufacturing

- Flat Glass

- Used in windows, doors, and architectural glass.

- Ensures strength, durability, and clarity for residential and commercial structures.

- Container Glass

- Essential for producing bottles, jars, and other containers.

- Offers high chemical stability, ensuring food and beverages remain safe.

- Specialty Glass

- Includes glass for solar panels, automotive applications, and optical devices.

- Requires ultra-pure silica sand for precise optical and mechanical properties.

- Fiberglass

- Used in insulation, roofing materials, and reinforcement products.

- Silica sand contributes to the durability and heat resistance of fiberglass.

- Decorative Glass

- Found in artistic creations, mirrors, and ornamental glassware.

- Provides brilliance and aesthetic appeal.

Benefits of Silica Sand in Glassmaking

- Exceptional Transparency: High-purity silica sand ensures clear and pristine glass.

- Versatility: Suitable for a wide range of glass types and applications.

- Eco-Friendliness: Recyclable and reusable, making it a sustainable material.

- Durability: Produces glass resistant to environmental and mechanical stress.

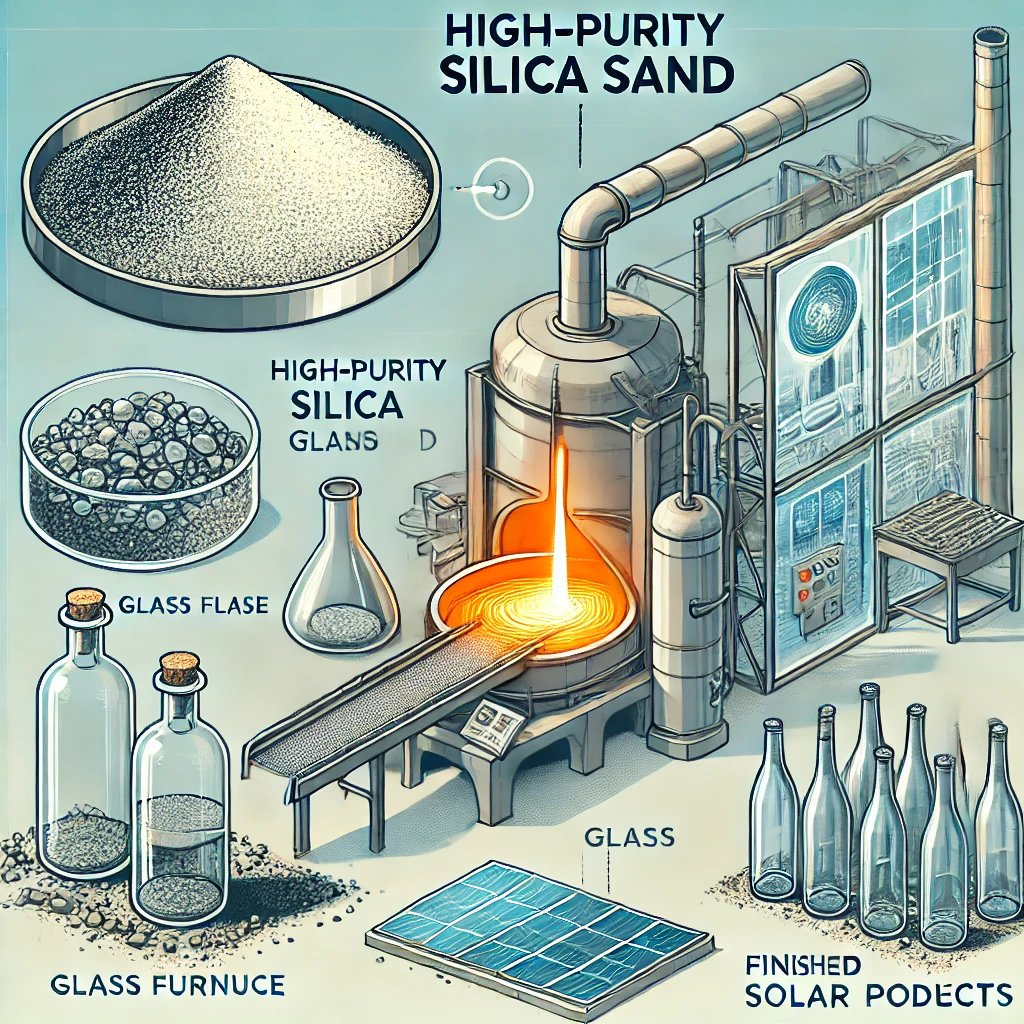

Glassmaking Using Silica Sand

- Preparation: High-purity silica sand is cleaned, sorted, and combined with soda ash, limestone, and other materials.

- Melting: The mixture is heated in a furnace to over 1,700°C (3,092°F) until it forms molten glass.

- Shaping: Molten glass is molded or blown into desired forms, such as sheets, bottles, or fibers.

- Cooling and Finishing: The glass is cooled and treated to enhance its properties.

Sourcing High-Quality Silica Sand for Glass Production Process

The quality of silica sand directly impacts the performance of the final glass product. Key factors to consider include:

- Purity Levels: High silica content with minimal impurities.

- Grain Size Consistency: Ensures uniform melting during glassmaking.

- Reliable Suppliers: Partner with trusted companies for premium-grade silica sand tailored to glass manufacturing needs.

FAQs About Silica Sand in Glass

- Why is silica sand essential for glass production?

- Silica sand provides the primary ingredient (silicon dioxide) needed to create durable and transparent glass.

- Can silica sand impurities affect glass quality?

- Yes, impurities like iron can cause discoloration and reduce clarity, especially in clear or optical glass.

- What industries rely on silica sand-based glass?

- Construction, automotive, electronics, renewable energy, and consumer goods are major users of silica sand-based glass.

Conclusion

Silica sand is the foundation of glass manufacturing, offering unmatched clarity, strength, and versatility. From windows and bottles to solar panels and optical devices, silica sand is an irreplaceable resource in producing high-quality glass products. Choosing high-purity silica sand from reliable suppliers ensures that the glass meets industry standards and performs flawlessly.

For more information on sourcing silica sand for glass manufacturing or exploring its applications, contact us today or browse our website for detailed insights!