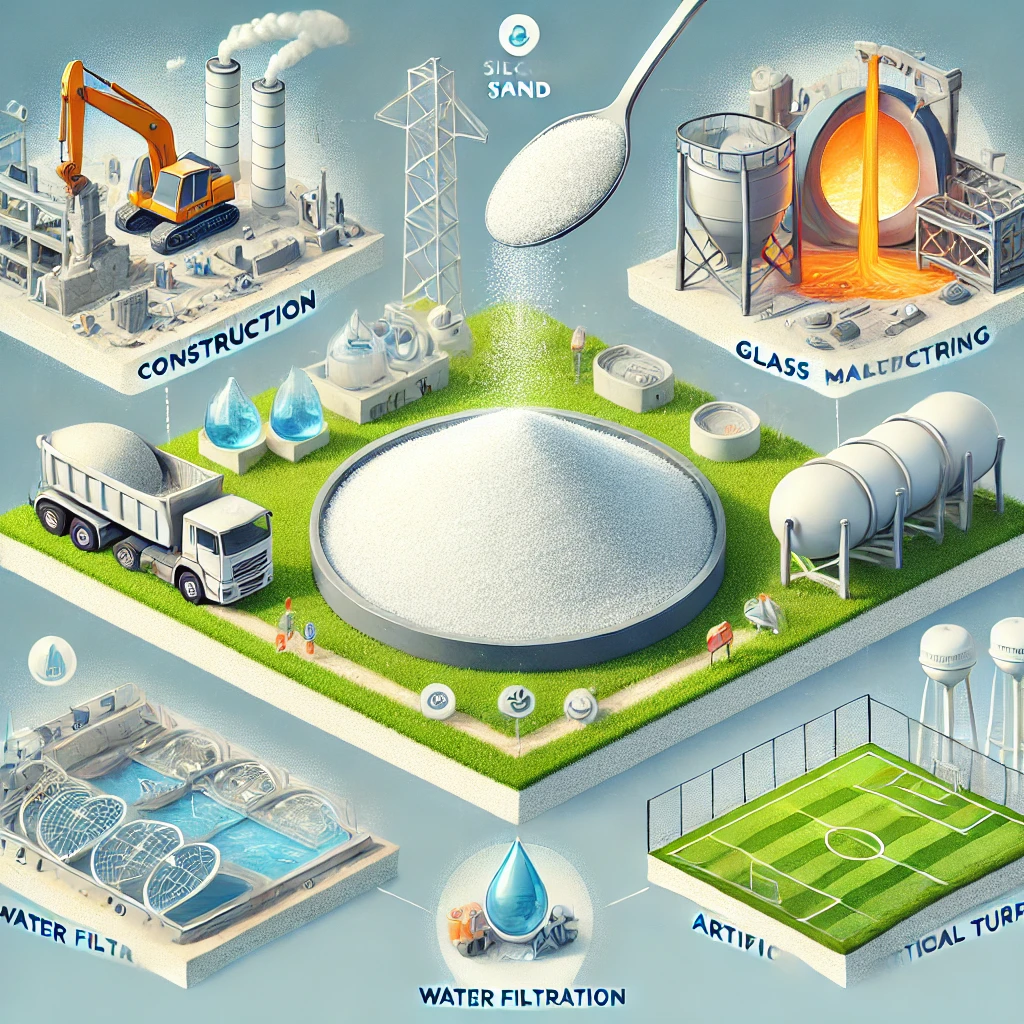

Silica sand plays a crucial role in several industries, including construction, sports, manufacturing, and even healthcare. However, not all silica sand is created equal. This ensures that the sand meets the required standards for specific applications is essential. This is where certifications come into play. These certifications validate the quality, safety, and performance of silica sand, ensuring it meets the specific requirements of each industry.

In this article, we will explore the key certifications that silica sand must meet across various industries. This ensures both regulatory compliance and high-quality performance.

1. Construction Industry

Key Certifications for Silica Sand:

- ISO 9001 (Quality Management System)

Silica sand in construction, particularly for concrete production, needs to meet international quality management standards. The ISO 9001 certification ensures that the product consistently meets customer and regulatory requirements. - EN 196-1 (European Standard for Cement and Aggregates)

EN 196-1 certification is vital for silica sand in cement and concrete applications. It ensures that the sand meets European standards for physical and chemical properties, making it suitable for construction purposes. - CE Marking

This certification ensures that the silica sand complies with EU health, safety, and environmental protection standards. It is required for construction products sold within the European Union. - ASTM Standards (American Society for Testing and Materials)

Silica sand used in construction materials must meet specific ASTM standards, which cover everything from particle size to chemical composition.

Why It’s Important:

These certifications guarantee that silica sand used in construction is durable, consistent, and safe for structural applications, ensuring the quality and safety of the finished product.

2. Sports Industry (Equestrian, Golf, Volleyball, etc.)

Key Certifications for Silica Sand:

- EN 196-1 (European Standard for Sand)

Silica sand used for sports surfaces, such as beach volleyball courts or equestrian arenas, needs to be certified for uniform particle size and consistency. The EN 196-1 certification assures that the sand meets the required specifications for these high-performance environments. - ISO 9001 (Quality Management)

Quality assurance is crucial in the sports industry. ISO 9001 certification ensures that the silica sand meets high standards for consistency and safety in sports applications. - FIFA Quality Certification (For Sports Surfaces)

For silica sand used in football pitches or similar surfaces, the FIFA Quality Certification ensures that the sand provides the necessary surface for top-level play, with appropriate drainage and texture.

Why It’s Important:

For sports applications, the silica sand must provide a reliable, safe, and consistent surface that supports performance while minimizing injury risks. Certification ensures that the sand used in these environments meets all necessary quality and safety standards.

3. Manufacturing and Industrial Applications

Key Certifications for Silica Sand:

- ISO 14001 (Environmental Management Systems)

Silica sand used in manufacturing processes, such as glass production or casting, must meet environmental management standards. The ISO 14001 certification ensures that silica sand production is carried out with minimal environmental impact, including waste management and resource use. - ISO 9001 (Quality Management System)

For industrial applications, ISO 9001 ensures that silica sand is consistent in quality and performance, essential for industries requiring high-precision and high-quality raw materials. - ROHS (Restriction of Hazardous Substances)

For silica sand used in industries like electronics, ROHS certification ensures that the sand is free of harmful substances such as lead and mercury, which could affect the quality of products like semiconductors or solar panels.

Why It’s Important:

Silica sand used in industrial applications must meet both quality and environmental standards to ensure it is safe for use and sustainable for long-term production. These certifications offer peace of mind regarding product safety, environmental responsibility, and high performance.

4. Healthcare and Pharmaceutical Industry

Key Certifications for Silica Sand:

- USP (United States Pharmacopeia)

USP certification is critical for silica sand used in pharmaceutical manufacturing, especially when it comes to excipients in drug formulation. This certification ensures that the silica sand meets strict quality standards for safety and purity. - ISO 13485 (Medical Device Quality Management)

Silica sand used in medical applications, such as in the production of medical devices or pharmaceutical equipment, must meet ISO 13485 standards, which ensure that products used in healthcare applications are of high quality and safe for use. - FDA (Food and Drug Administration)

For silica sand used in the production of medical products, the FDA certification ensures that it complies with strict safety and quality standards, especially for products that come in contact with the human body.

Why It’s Important:

For the healthcare industry, purity and safety are paramount. Certifications like USP and ISO 13485 ensure that the silica sand used in pharmaceutical and medical applications meets stringent standards, minimizing the risk of contamination or adverse reactions.

5. Environmental and Waste Management Industry

Key Certifications for Silica Sand:

- ISO 14001 (Environmental Management Systems)

ISO 14001 certification ensures that the silica sand used in environmental applications is sourced and processed sustainably. This certification is especially relevant for sand used in filtration systems or waste management. - EMAS (Eco-Management and Audit Scheme)

EMAS certification ensures that companies involved in silica sand production and processing adhere to rigorous environmental standards, reducing their carbon footprint and promoting eco-friendly practices.

Why It’s Important:

In the environmental and waste management industry, silica sand must be processed and used in ways that minimize environmental impact. Certifications like ISO 14001 and EMAS demonstrate a commitment to sustainability and responsible sourcing.

Conclusion

Certifications for silica sand play a crucial role in ensuring that the material meets the specific quality, safety, and environmental standards required by each industry. Whether for construction, sports, industrial manufacturing, or healthcare, certifications like ISO 9001, EN 196-1, and USP help ensure that silica sand is safe, durable, and high-performing for its intended use. By choosing certified silica sand, companies can trust that they are using a material that complies with regulatory standards, boosts product quality, and promotes sustainability.