Choosing the Best Silica Sand for Precast Concrete Products

Precast products are widely used in construction for their strength, durability, and versatility. A key ingredient in ensuring the quality of precast is silica sand. Its unique properties significantly impact the performance and longevity of precast elements. This article explores how to choose the best silica sand for precast products and why it matters for your concrete projects.

Why Silica Sand is Essential for Precast Concrete

- Strength and Durability

- Silica sand enhances the compressive and tensile strength of precast concrete, ensuring it can withstand heavy loads and environmental stress.

- Uniformity in Texture

- Fine silica sand provides a smooth finish to precast elements, essential for aesthetic and structural integrity.

- Improved Workability

- The sand’s consistent grain size ensures better mixing and application, reducing voids and improving the overall quality of the concrete.

- Compatibility with Cement

- High-purity silica sand reacts well with cement, optimizing the hydration process and enhancing concrete strength.

Factors to Consider When Choosing Silica Sand

- Particle Size Distribution

- Fine sand (e.g., 100 to 200 mesh) is ideal for smooth finishes and precision in smaller precast elements.

- Coarser sand is suitable for structural components requiring higher strength.

- Purity

- Look for silica sand with a purity of at least 95% SiO₂ for optimal performance.

- High-purity sand reduces the risk of impurities that can weaken the concrete.

- Grain Shape

- Rounded or sub-angular grains improve workability and reduce water demand in concrete mixes.

- Moisture Content

- Low moisture levels in sand ensure consistent water-to-cement ratios during mixing.

- Source and Supplier

- Choose reliable suppliers who can provide consistent quality and adhere to industry standards like ASTM C33.

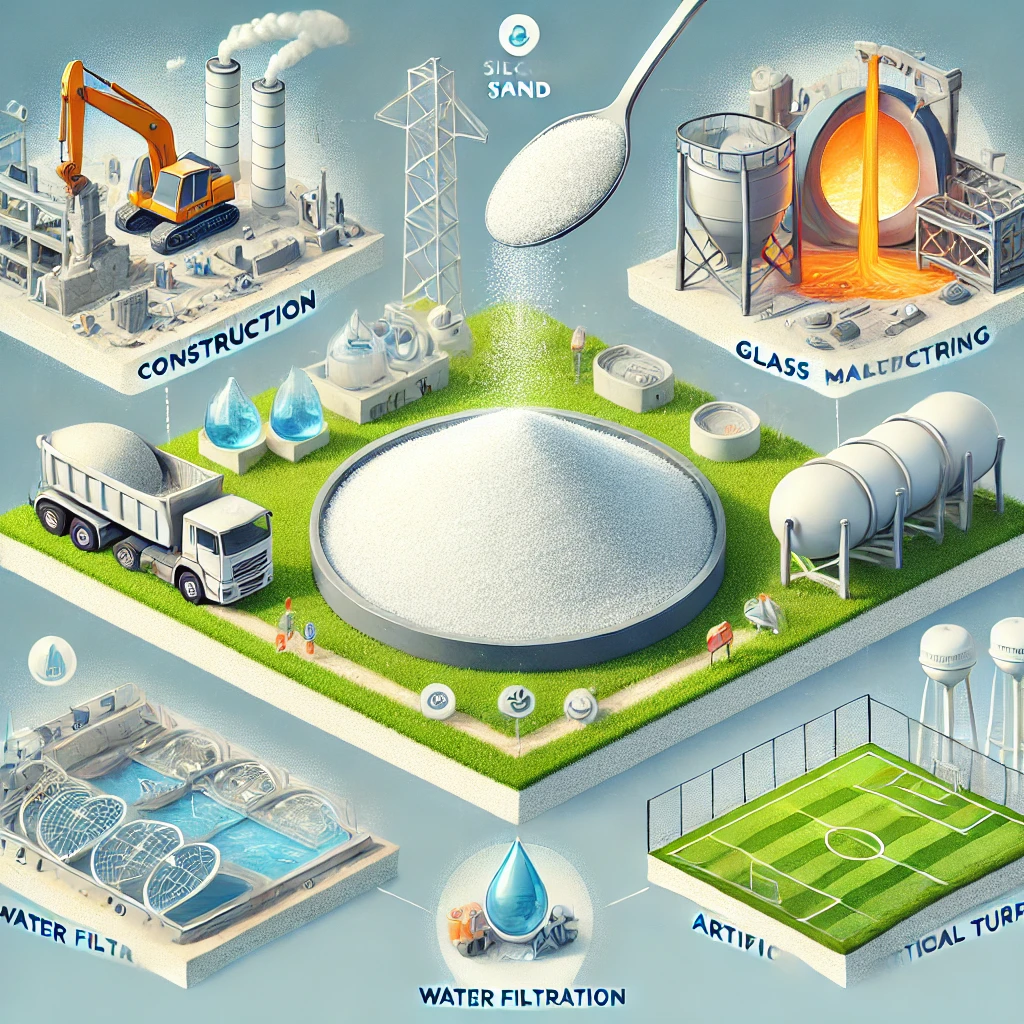

Applications of Silica Sand in Precast Concrete Products

- Architectural Panels

- Fine silica sand ensures smooth surfaces for decorative panels and facades.

- Beams and Columns

- Coarser sand enhances the strength and load-bearing capacity of structural elements.

- Paving Blocks

- Silica sand improves the durability and wear resistance of precast concrete pavers.

- Drainage Pipes

- Used in precast pipes, silica sand ensures long-lasting performance under varying conditions.

- Retaining Walls

- Provides the necessary strength and stability for precast retaining walls in landscaping and infrastructure projects.

Benefits of Using High-Quality Silica Sand

- Consistency:

- Ensures uniform texture and strength across all precast products.

- Durability:

- Reduces the risk of cracking and shrinkage, enhancing the lifespan of precast elements.

- Aesthetic Appeal:

- Smooth surfaces improve the visual quality of architectural products.

- Efficiency:

- Better mixing and workability reduce production time and costs.

How to Source the Best Silica Sand for Precast Concrete

- Request Material Specifications

- Obtain detailed data sheets from suppliers to evaluate particle size, purity, and moisture content.

- Conduct Quality Tests

- Perform lab tests to ensure the sand meets your project’s specific requirements.

- Visit Local Suppliers

- If possible, inspect the sand at the source to verify quality.

- Adhere to Standards

- Ensure the sand complies with industry standards like ASTM C33 for concrete aggregates.

FAQs About Silica Sand for Precast Concrete

- Can silica sand improve concrete strength?

- Yes, silica sand enhances the compressive and tensile strength of concrete.

- What is the ideal particle size for precast concrete?

- The ideal size depends on the application, with fine sand preferred for smooth finishes and coarser sand for structural components.

- Is high-purity silica sand necessary for all precast products?

- High-purity sand is essential for structural integrity and durability, especially in critical applications.

Conclusion

Choosing the best silica sand for precast concrete products is crucial for ensuring strength, durability, and aesthetic quality. By focusing on factors like particle size, purity, and supplier reliability, you can achieve superior results for your construction projects.

For more information on sourcing high-quality silica sand or optimizing your precast mixes, contact us today or visit our website!