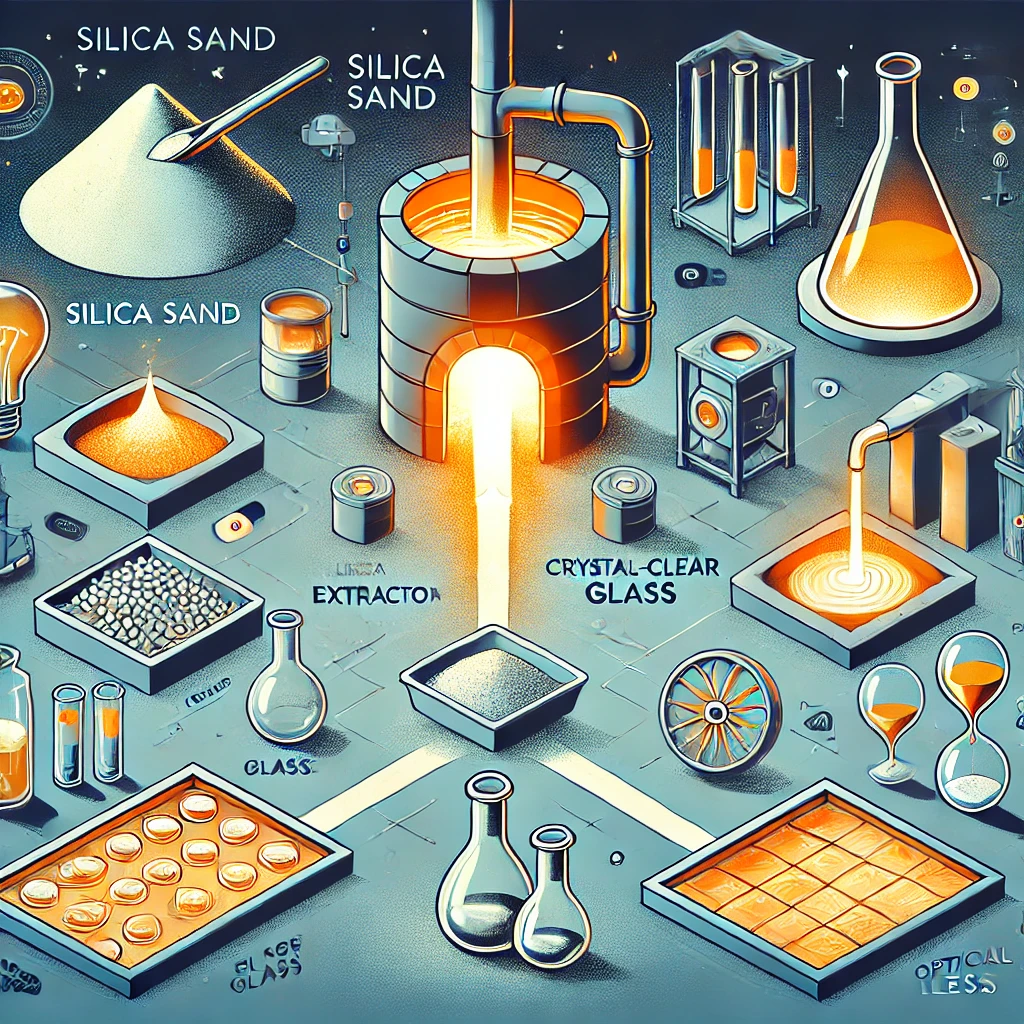

From Silica Sand to Crystal Clear Glass: The Manufacturing Process

Glass is an essential material in our everyday lives, from windows and bottles to high-tech displays and solar panels. But have you ever wondered how this transparent marvel is made? The journey begins with silica sand. This article will take you through the fascinating process of transforming silica sand into crystal-clear glass.

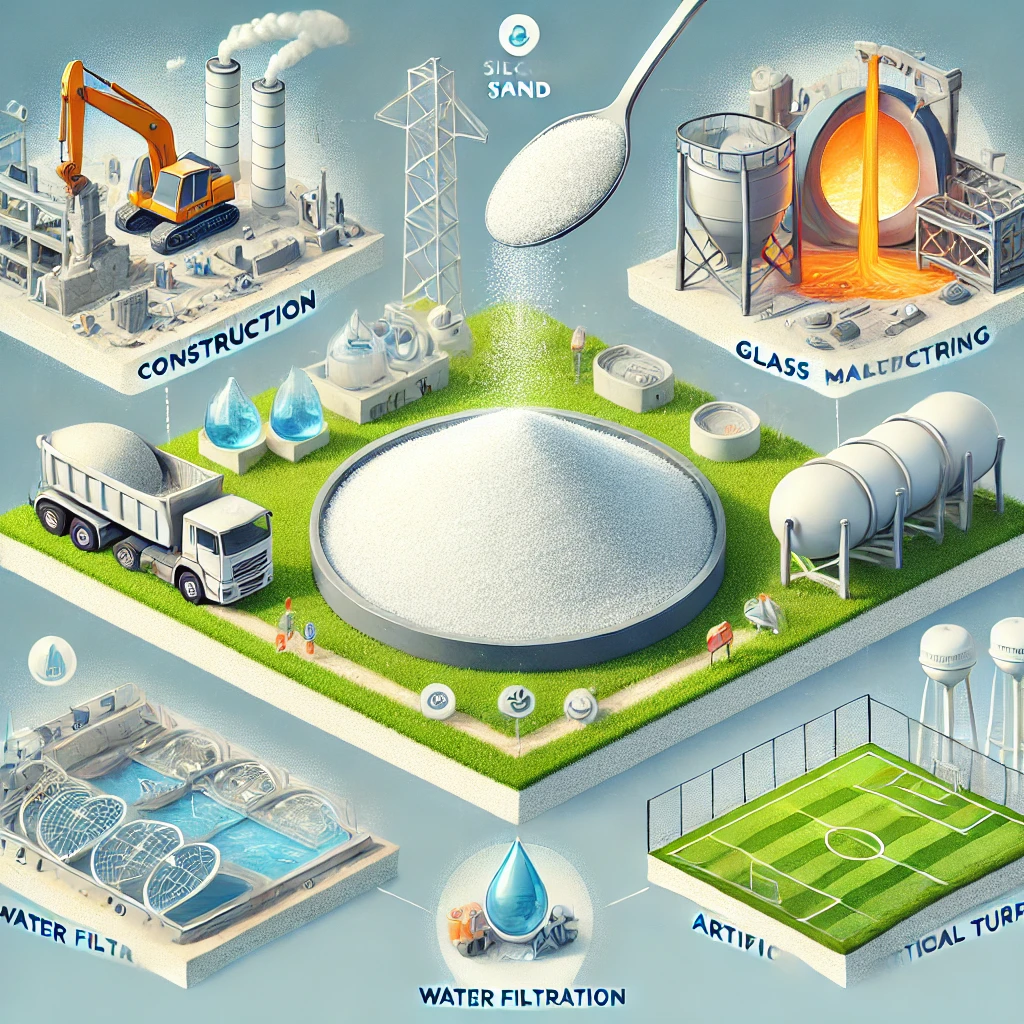

The Importance of Silica Sand in Glass Manufacturing

Silica sand, composed primarily of silicon dioxide (SiO₂), is the primary raw material for glass production. Its high purity and unique properties make it indispensable for creating durable, clear, and heat-resistant glass products.

Step-by-Step Glass Manufacturing Process

The production of glass involves several key steps:

1. Mining and Preparation of Silica Sand

The process begins with the extraction of high-purity silica sand from quarries or mines. We then wash the sand, screen it, and process it to remove impurities. This includes clay, iron, and other minerals that could affect the glass quality.

2. Batch Mixing

We combine silica sand with other materials such as:

- Soda Ash: Lowers the melting point of silica.

- Limestone: Enhances durability and stability.

- Recycled Glass (Cullet): Reduces energy consumption and raw material demand.

The precise proportions of these ingredients depend on the type of glass we produce.

3. Melting

The mixture we heat in a furnace at temperatures exceeding 1700°C (3092°F). At this extreme heat, the silica sand and other components melt into a viscous liquid.

4. Shaping the Glass

We shape the molten glass into the desired form using various methods, such as:

- Float Process: For flat glass used in windows and mirrors.

- Blowing: For bottles and jars.

- Fiber Drawing: For fiberglass and insulation materials.

5. Annealing

After shaping, the glass is slowly cooled in a controlled process known as annealing. This step relieves internal stresses, preventing the glass from cracking or breaking.

6. Finishing and Inspection

The final glass products are polished, coated (if necessary), and inspected for quality. Any defective items are recycled back into the production process.

Types of Glass Produced

Different types of glass can be manufactured using silica sand, including:

- Container Glass: Bottles, jars, and other packaging.

- Flat Glass: Windows, doors, and solar panels.

- Specialty Glass: Optical lenses, lab equipment, and high-tech screens.

Environmental Considerations

Modern glass manufacturing focuses on sustainability by:

- Using recycled cullet to lower energy consumption.

- Implementing cleaner production techniques.

- Ensuring responsible silica sand mining practices.

Conclusion

The transformation of silica sand into crystal-clear glass is a testament to human ingenuity and technological advancement. This versatile material plays a vital role in industries ranging from construction to electronics. Understanding the manufacturing process highlights the importance of high-quality silica sand and sustainable practices.

If you’re in need of premium silica sand for glass production, reach out to us today. We provide high-purity silica sand that ensures exceptional results for all your glass manufacturing needs.

Write something…