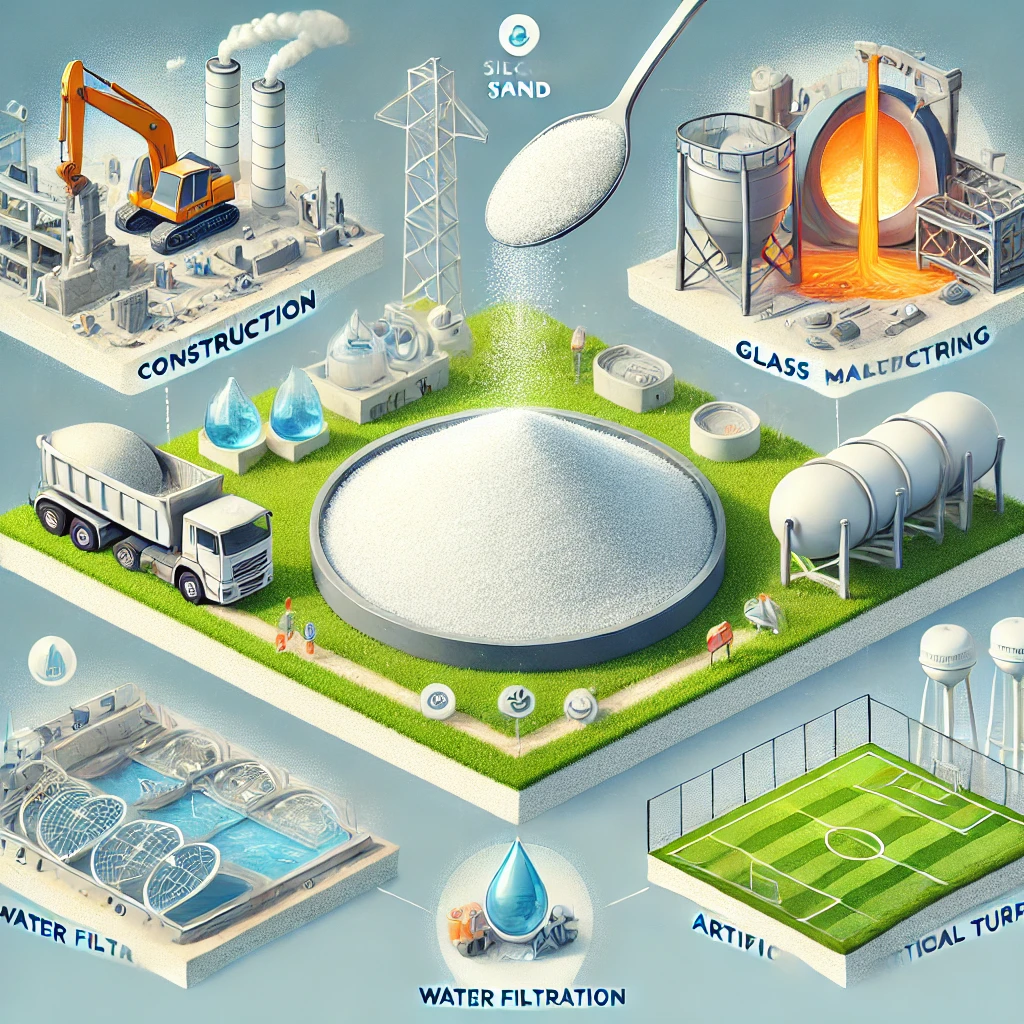

Silica sand is widely used in industries ranging from construction to electronics, thanks to its high purity and insulating properties. One of its critical attributes is resistivity, which plays a pivotal role in applications like electrical insulation, grounding systems, and high-voltage equipment. This article delves into what resistivity is, the factors affecting it, and how the resistivity is utilized across industries.

What is Resistivity?

Resistivity refers to a material’s ability to resist the flow of electric current. Measured in ohm-meters (Ω·m), higher resistivity indicates better insulating properties. With its high resistivity, is an excellent choice for applications requiring electrical insulation and thermal stability.

Factors Affecting Resistivity

The resistivity depends on several factors, including:

- Purity:

- High-purity exhibits better resistivity due to minimal conductive impurities like iron or aluminum.

- Moisture Content:

- Moisture significantly reduces resistivity as water conducts electricity.

- Dry is preferred in insulation applications.

- Grain Size:

- Finer grains provide a larger surface area, which may trap more moisture and reduce resistivity.

- Coarser grains tend to maintain higher resistivity.

- Compaction:

- Densely packed has better electrical insulation due to reduced air gaps.

- Temperature:

- Resistivity generally decreases as temperature increases, making silica sand ideal for applications requiring thermal stability.

Resistivity Values

| Condition | Resistivity (Ω·m) |

|---|---|

| Dry and Pure Silica Sand | ~10⁶ – 10⁸ Ω·m |

| Silica Sand with Moisture | ~10² – 10⁴ Ω·m |

| High-Temperature Conditions | ~10⁴ – 10⁶ Ω·m |

Applications of Silica Sand Based on Resistivity

- Electrical Insulation:

- Used in high-voltage equipment to prevent electrical leakage.

- Essential in transformers, insulators, and switchgear.

- Grounding Systems:

- Mixed with other materials to achieve desired resistivity levels for grounding applications.

- Thermal Insulation:

- High resistivity coupled with thermal stability makes silica sand ideal for heat-resistant coatings and refractory materials.

- Electronics and Semiconductors:

- High-purity silica sand is processed to produce silicon, which is the foundation of semiconductors.

- Construction:

- Used in concrete and mortar for its insulating and thermal properties.

How to Enhance Silica Sand Resistivity

Industries can improve the resistivity of silica sand by:

- Drying: Ensuring minimal moisture content.

- Purification: Removing conductive impurities through washing and screening.

- Compaction: Packing sand tightly to reduce air gaps.

Testing Resistivity of Silica Sand

To measure silica sand resistivity, the following methods are commonly used:

- Four-Point Probe Method: Measures resistivity by passing current through the sample and measuring voltage drop.

- ASTM Standards: Follow guidelines like ASTM D257 for precise resistivity measurements.

Conclusion

Silica sand’s resistivity is a critical property that determines its suitability for various industrial applications. By understanding and optimizing factors like moisture content, purity, and compaction, industries can leverage silica sand’s insulating properties for enhanced performance.

Whether you’re working in electronics, construction, or power systems, silica sand’s high resistivity ensures reliability and efficiency. For more information about sourcing high-quality silica sand, explore our products and services.