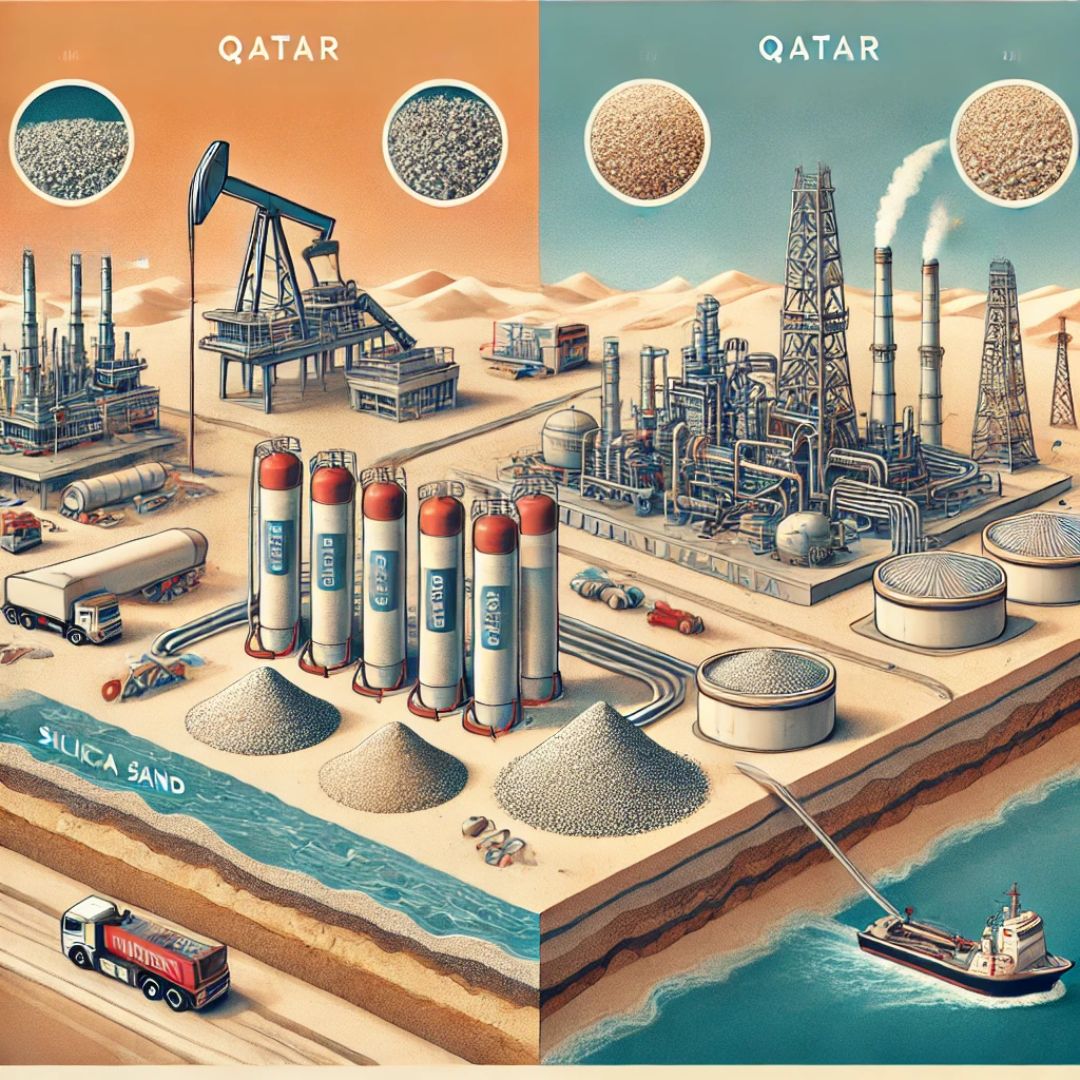

Silica sand, a high-purity form of quartz sand, plays a crucial role in Qatar’s oil and gas sector. With its unique properties, silica sand supports various processes in exploration, production, and refining. Here, we delve into the key applications and benefits of silica sand in this vital industry.

1. Hydraulic Fracturing (Fracking)

One of the primary uses of silica sand in the oil and gas industry is as a proppant in hydraulic fracturing. This process involves injecting a mixture of water, chemicals, and silica sand into underground rock formations to extract oil and natural gas.

- Why Silica Sand?

- Its round and durable grains keep fractures in the rock open, allowing oil or gas to flow freely.

- The high-purity silica ensures optimal performance without contaminating the resource.

- Benefits in Qatar:

- The abundance of natural gas reserves in Qatar makes fracking a critical technology, and silica sand is indispensable in improving extraction efficiency.

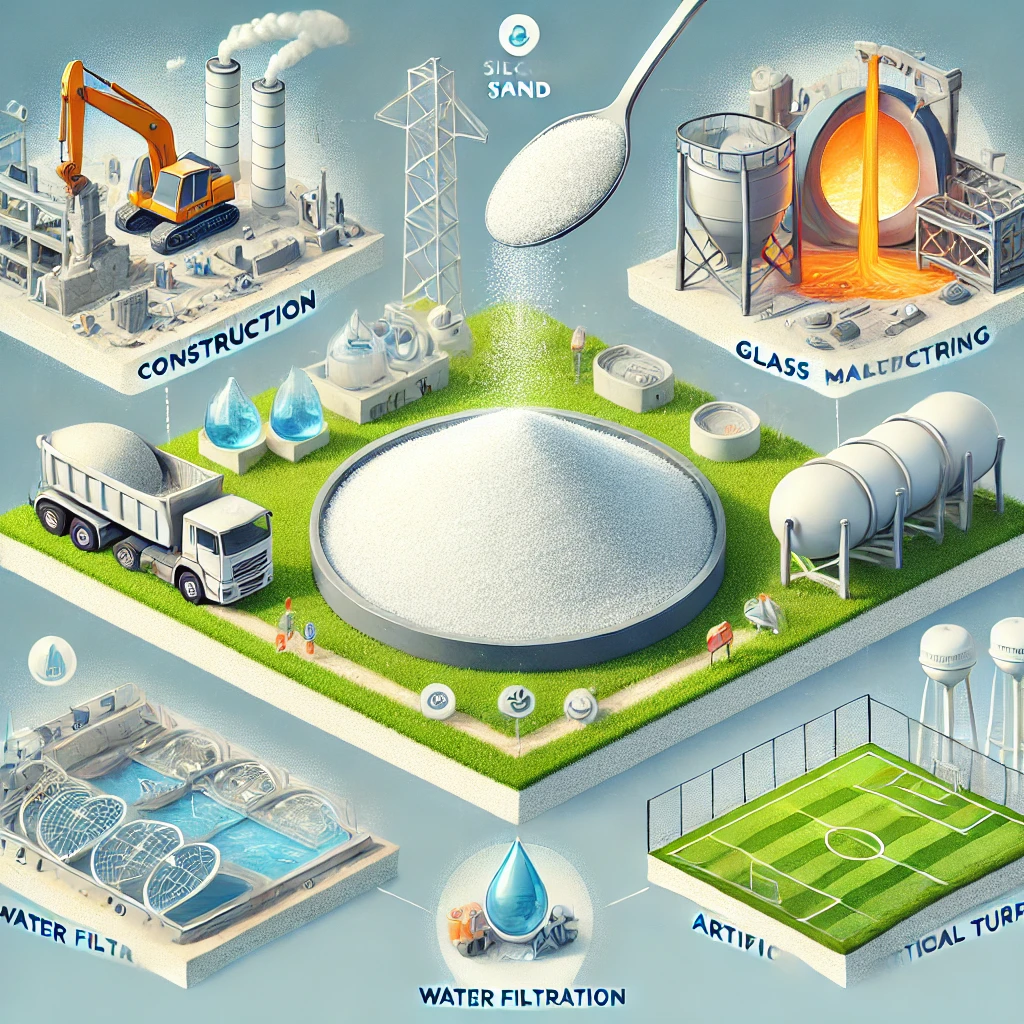

2. Filtration in Processing Plants

Silica sand is a filtration medium in refineries and processing plants to remove impurities from liquids and gases.

- Key Features:

- The sand’s uniform particle size and chemical inertness make it highly effective in filtering contaminants.

- It supports processes like water treatment, ensuring that water used in operations is clean and reusable.

- Benefits in Qatar:

- With Qatar’s focus on sustainable practices, silica sand aids in maintaining eco-friendly operations in the oil and gas sector.

3. Sand Control in Wells

Silica sand is also used for sand control to prevent the intrusion of formation sand into wells during oil and gas extraction. This ensures smoother operations and prevents equipment wear and tear.

- How It Works:

- Silica sand is packed around the well’s screen or casing to filter out unwanted particles.

- Advantages:

- Reduces operational downtime due to sand-related blockages.

- Protects equipment and extends its lifespan.

4. Catalyst Support in Refining

In oil refining, silica sand serves as a catalyst support in processes like cracking, where hydrocarbons are broken down into smaller molecules.

- Why It’s Effective:

- Its high surface area and thermal stability make it an ideal material for supporting catalytic reactions.

- Impact in Qatar:

- Enhances the efficiency of Qatar’s refineries, which are key to the country’s energy exports.

5. Pipeline Protection and Construction

Silica sand is often used in pipeline construction for transporting oil and gas. It serves as a base material to:

- Provide stability and cushioning for pipelines.

- Prevent damage from soil movement or external pressure.

- Relevance in Qatar:

- With extensive pipeline networks for natural gas exports, silica sand helps ensure safe and reliable transportation infrastructure.

6. Well Stimulation

Silica sand is also used in acidizing treatments, a process where acid is pumped into the well to improve permeability and flow rates.

- How Silica Sand Contributes:

- It enhances the effectiveness of acids by stabilizing the well’s structure.

Conclusion

Silica sand is an indispensable material in Qatar’s oil and gas sector, supporting critical processes from extraction to refining. Its unique properties make it essential for enhancing efficiency, protecting infrastructure, and enabling sustainable operations. As Qatar continues to lead in energy production, the role of silica sand will remain vital in maintaining the industry’s growth and success.

Need High-Quality Silica Sand?

If you’re looking for premium silica sand for oil and gas applications in Qatar, contact us for reliable sourcing and expert guidance.