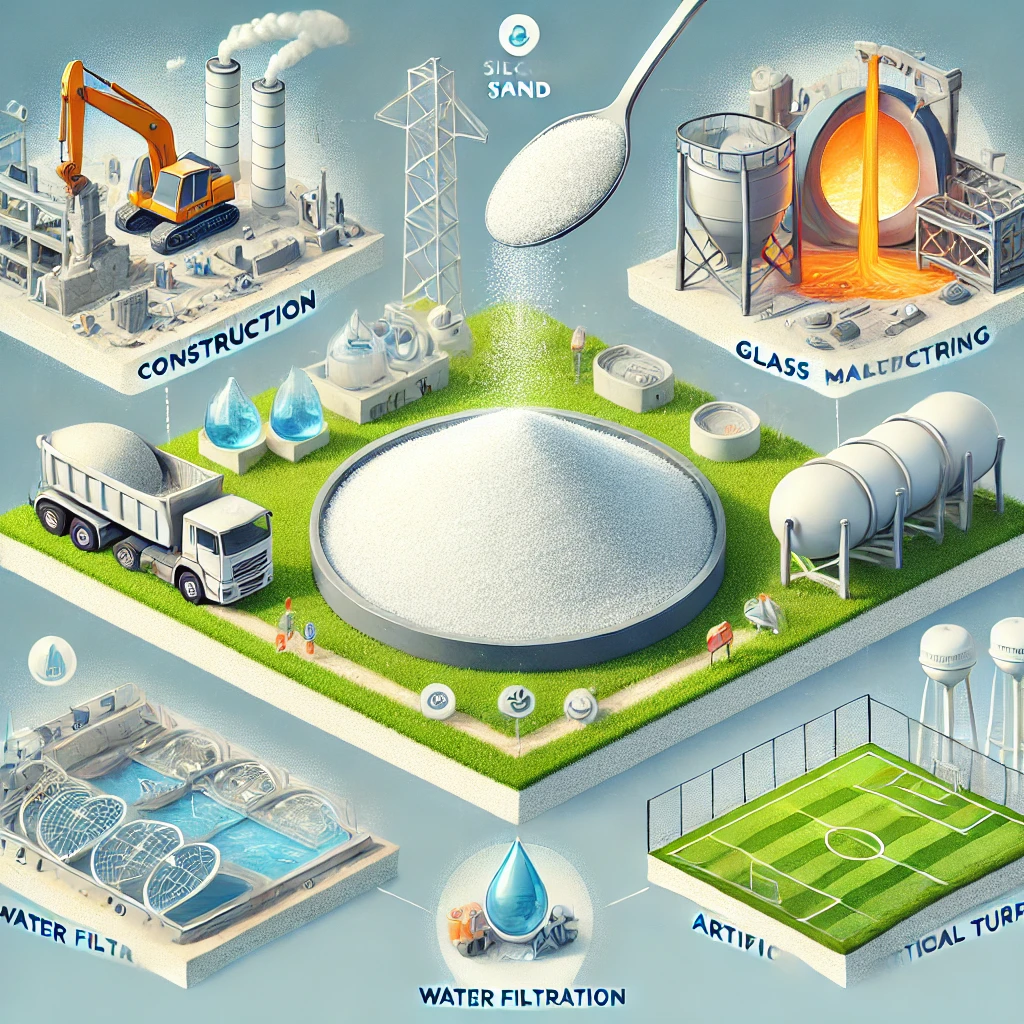

The Role of Silica Sand in Mortar and Cement

Silica sand is a key ingredient in the production of mortar and cement, two of the most widely used materials in construction. Its unique properties, such as high silica content, durability, and uniform particle size, make it indispensable for creating strong, durable, and versatile building materials. In this article, we’ll explore the vital role silica sand plays in mortar and cement, its benefits, and its applications.

What is Silica Sand?

Silica sand, also known as quartz sand, is a naturally occurring material made up of fine quartz grains. It is processed to meet the specific needs of industries like construction, where its high purity and consistent quality are benefits.

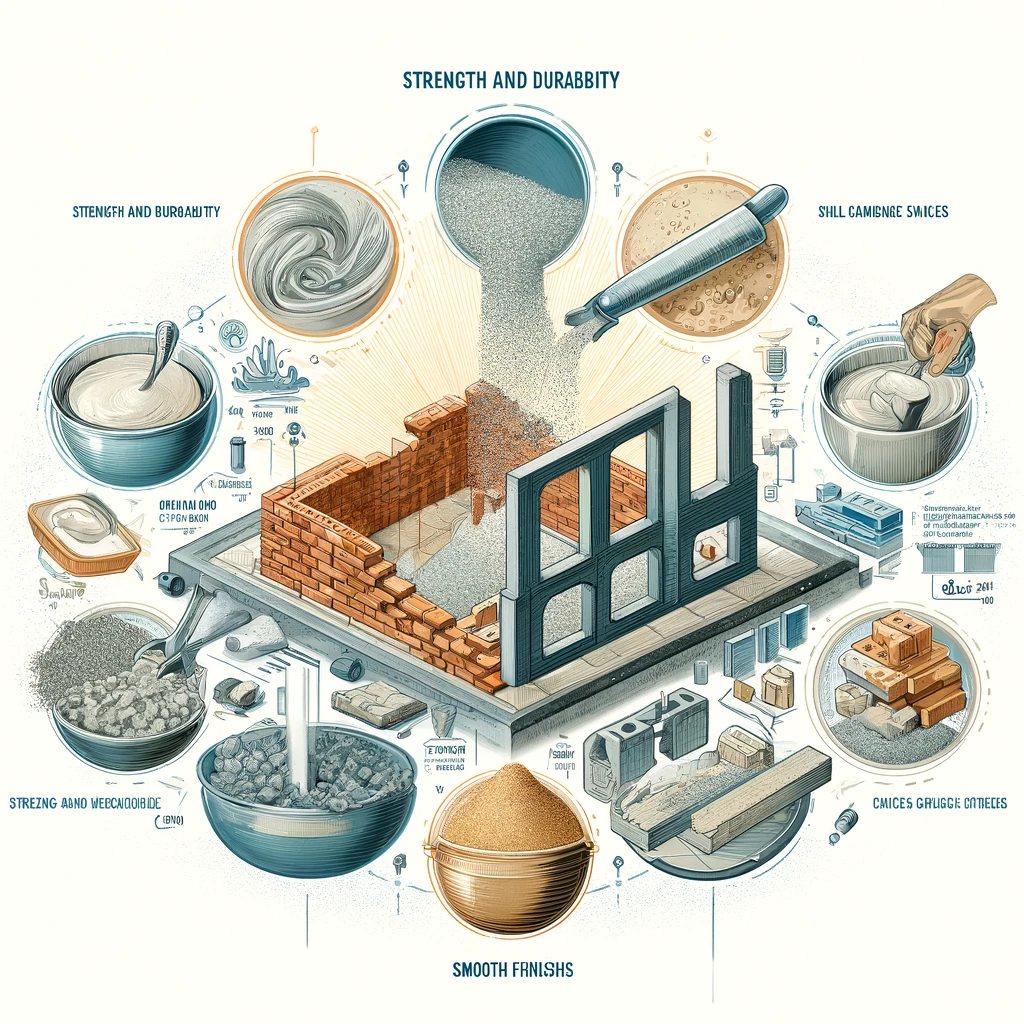

Silica Sand in Mortar

1. Filler Material

- Silica sand acts as a fine aggregate in mortar, filling the spaces between larger aggregates like gravel.

- It ensures a smooth, cohesive mixture that is easy to work with.

2. Enhanced Strength

- The high silica content in sand provides strength to the mortar, making it suitable for load-bearing applications.

- It helps improve the compressive strength and tensile performance of the finished structure.

3. Workability

- Silica sand improves the plasticity and workability of mortar, making it easier to spread and shape during application.

4. Resistance to Shrinkage

- By reducing shrinkage and cracking, silica sand ensures long-lasting and durable mortar joints.

5. Aesthetic Finishes

- Fine silica sand is used in decorative mortars, providing smooth and consistent textures for aesthetic applications.

Silica Sand in Cement

1. Raw Material

- Silica sand is a key component in the manufacture of cement, where it serves as a source of silicon dioxide (SiO₂).

- It combines with other materials like limestone and clay to form clinker, which is ground into cement.

2. Strength and Durability

- Silica sand enhances the chemical reactions during cement production, improving the strength and durability of the final product.

3. Heat Resistance

- The addition of silica sand in cement increases its heat resistance, making it suitable for high-temperature applications like refractory materials.

4. Sustainability

- Silica sand reduces the amount of clinker required in cement production, lowering the carbon footprint and energy consumption.

Benefits of Using Silica Sand in Mortar and Cement

- Improved Strength: Enhances the structural integrity of mortar and cement.

- Durability: Increases resistance to weathering, moisture, and chemical exposure.

- Cost-Effectiveness: A readily available and affordable material that reduces overall production costs.

- Workability: Ensures smoother application and better adhesion.

- Aesthetic Appeal: Provides a consistent finish for decorative applications.

Applications of Silica Sand in Mortar and Cement

- Bricklaying Mortar

- Provides strong and durable joints for bricks and blocks.

- Plastering

- Used in fine mortars for creating smooth wall finishes.

- Concrete

- Enhances the strength and durability of concrete mixes.

- Refractory Mortars

- Provides heat resistance in high-temperature environments.

- Decorative Mortars

- Used for creating textured finishes and decorative elements.

How to Choose the Right Silica Sand for Mortar and Cement

- Particle Size:

- Fine sand for plastering and decorative mortars.

- Coarser sand for structural and load-bearing applications.

- Purity:

- High-purity silica sand ensures better performance and fewer impurities.

- Color:

- Choose sand that complements the desired aesthetic finish.

- Supplier Reliability:

- Source silica sand from reputable suppliers to ensure consistent quality.

FAQs About Silica Sand in Mortar and Cement

- Can silica sand be replaced with other materials?

- While alternatives exist, silica sand’s unique properties make it difficult to replicate in many applications.

- Is silica sand safe to use in construction?

- Yes, when handled responsibly, processed silica sand is safe and widely used in construction.

- How does silica sand improve mortar and cement durability?

- By enhancing strength, reducing shrinkage, and improving resistance to environmental factors.

Conclusion

Silica sand is an essential ingredient in mortar and cement, contributing to their strength, durability, and versatility. From creating strong structural joints to enhancing decorative finishes, silica sand plays a vital role in modern construction. By selecting high-quality silica sand tailored to your project needs, you can ensure superior results and long-lasting performance.

For more information on sourcing silica sand for mortar and cement or to explore its benefits, contact us today or visit our website!