Why Silica Sand is the Backbone of Glass Manufacturing

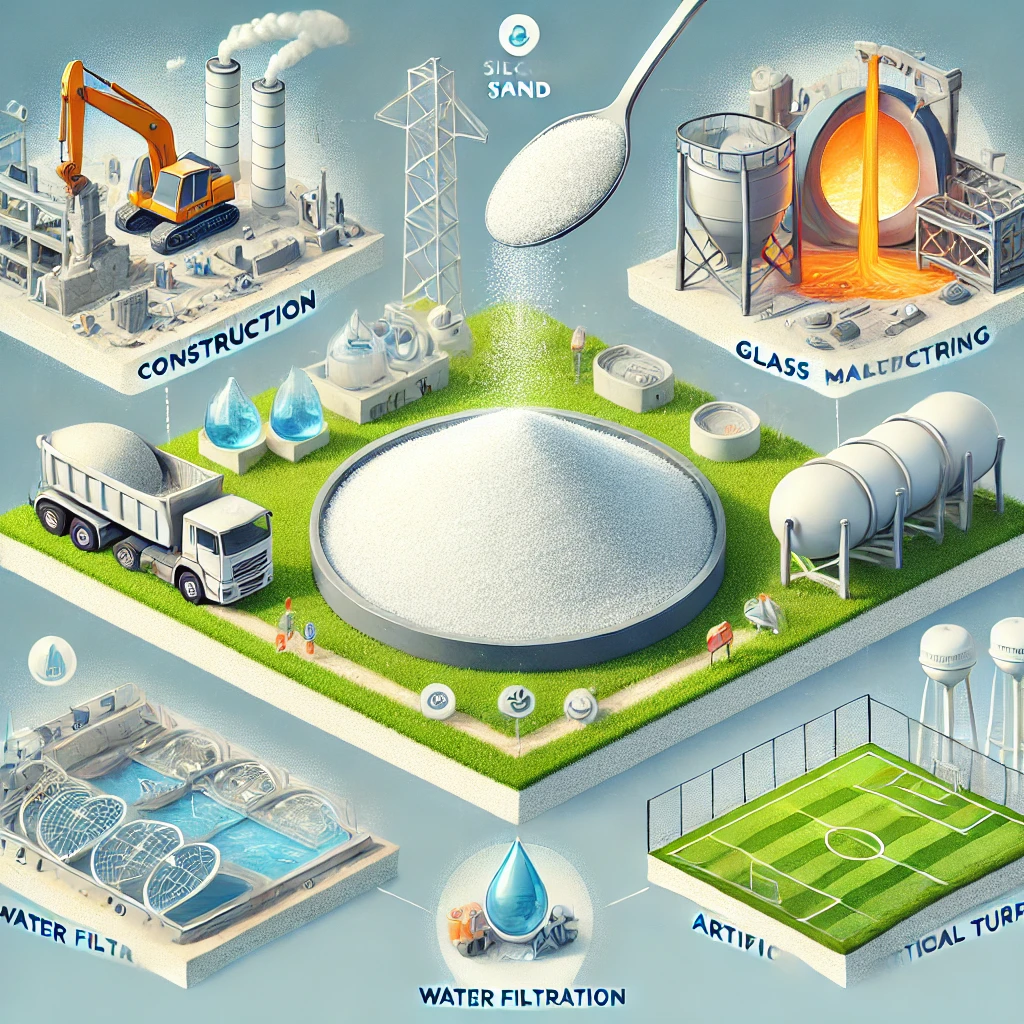

Glass is a material we encounter daily, from mirrors to bottles and screens. At the heart of this essential material lies silica sand, a key ingredient that makes glass production possible. In this article, we explore why silica sand is the backbone of glass manufacturing and its pivotal role in shaping modern industries.

What Makes Silica Sand Essential for Glass Manufacturing?

Silica sand is a high-purity material composed primarily of silicon dioxide (SiO₂). Its unique properties make it the ideal raw material for glass screens. Here’s why:

- High Silicon Dioxide Content: The high SiO₂ content ensures clarity and strength in glass products, making silica sand indispensable.

- Uniform Grain Size: Consistent grain size allows for uniform melting and mixing during the manufacturing process.

- Thermal Stability: Silica sand can withstand extreme temperatures, making it perfect for high-temperature glass production.

The Glass Manufacturing Process

Silica sand undergoes several steps to transform into the glass we use every day:

- Raw Material Preparation: Silica sand is cleaned and screened to remove impurities.

- Mixing: It is blended with other materials like soda ash, limestone, and recycled glass.

- Melting: The mixture is melted at temperatures exceeding 1700°C (3092°F).

- Shaping: The molten glass is shaped into the desired forms, such as sheets, bottles, or fibers.

- Cooling: The glass is gradually cooled to solidify its structure and enhance durability.

Applications of Silica Sand in Glassmaking

Silica sand is used in various types of glass production, including:

- Flat Glass: Used in windows, doors, and mirrors.

- Container Glass: Essential for bottles, jars, and other packaging.

- Fiberglass: Utilized in insulation and composite materials.

- Specialty Glass: Found in lenses, laboratory equipment, and electronic screens.

Benefits of Silica Sand in Glass Manufacturing

- Cost-Effectiveness: Abundant and easy to process, silica sand keeps production costs manageable.

- Sustainability: Glass made with silica sand can be recycled indefinitely without loss of quality.

- Versatility: Its adaptability allows for the creation of diverse glass products.

Environmental Considerations

While silica sand is crucial for glassmaking, mining and processing must be managed responsibly to minimize environmental impact. Sustainable practices include:

- Reducing energy consumption during processing.

- Using recycled glass to decrease raw material demand.

- Implementing land restoration projects post-mining.

Conclusion

Silica sand is the unsung hero of glass manufacturing, enabling the creation of products that enhance our lives daily. Its unique properties and versatility make it an essential resource for industries worldwide.

If you’re looking for high-quality silica sand for your glass manufacturing needs, contact us today. Our premium silica sand ensures exceptional results for all types of glass production.