Silica Sand Standards: Ensuring Quality and Performance

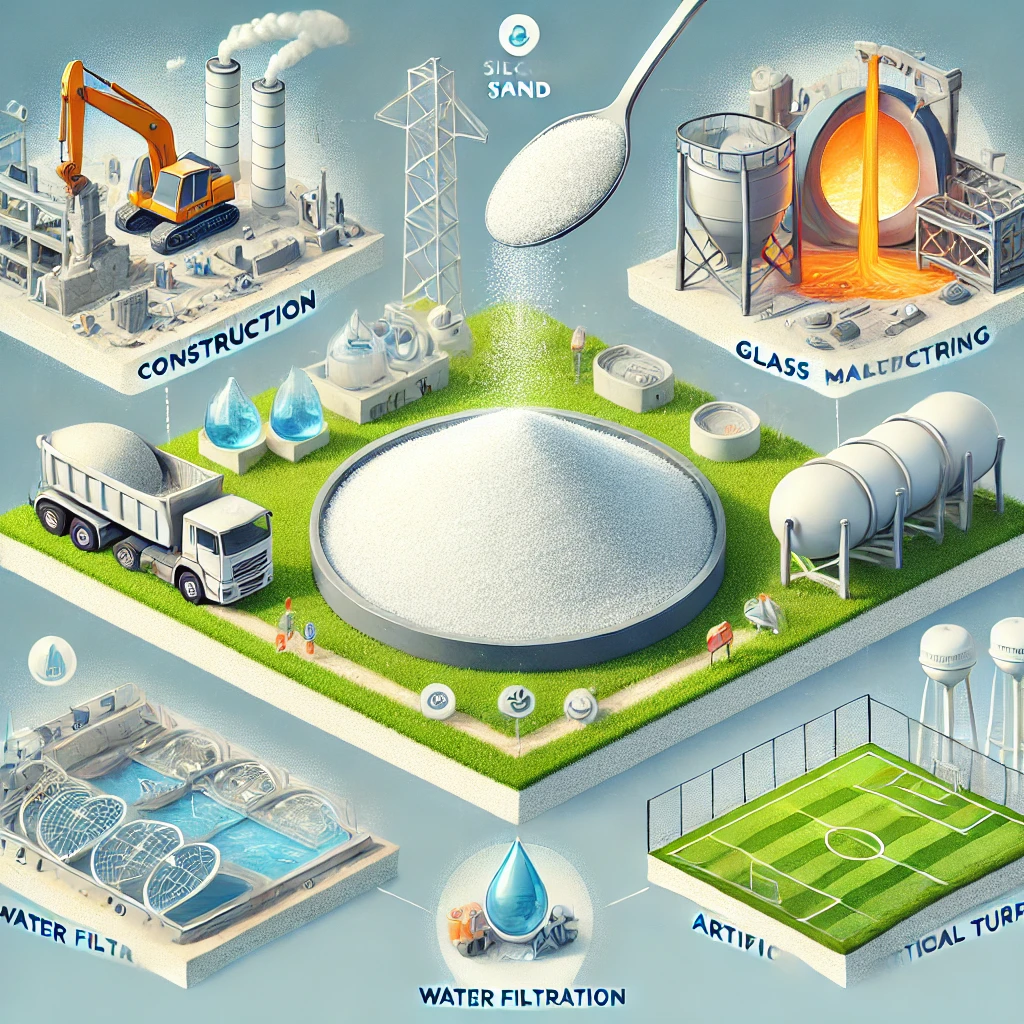

Silica sand is a vital material used in various industries, including construction, glass manufacturing, water filtration, and foundry casting. To ensure consistency, quality, and safety in its applications, silica sand must meet specific standards. These standards define the material’s physical, chemical, and mechanical properties, helping industries achieve optimal results. In this article, we’ll explore the key standards for silica sand, their significance, and how to ensure compliance.

Why Are Silica Sand Standards Important?

- Consistency in Quality

- Standards ensure uniformity in properties like particle size, purity, and chemical composition, crucial for industrial applications.

- Optimized Performance

- Meeting specific standards enhances the efficiency and durability of silica sand in applications like filtration and casting.

- Regulatory Compliance

- Adhering to recognized standards ensures compliance with industry regulations, reducing legal and operational risks.

- Safety

- Standards minimize risks associated with impurities and improper usage, protecting both workers and end-users.

Key Silica Sand Standards

- ASTM International Standards

- ASTM C144: Defines specifications for silica sand used in mortars.

- ASTM C778: Specifies silica sand requirements for concrete testing.

- ASTM D859: Covers testing for silica content in water.

- ISO Standards

- ISO 13503-2: Focuses on the particle size distribution and sphericity of silica sand for hydraulic fracturing.

- ISO 14688-1: Categorizes silica sand based on grain size and soil classification.

- European Standards (EN)

- EN 12904: Specifies silica sand requirements for use in water treatment.

- EN 196-1: Defines standards for silica sand in cement testing.

- Industry-Specific Standards

- Glass Manufacturing: Requires silica sand with high purity (typically 99.5% SiO₂) and low iron content.

- Foundry Casting: Emphasizes uniform grain size and high refractoriness for precision molding.

Key Parameters in Silica Sand Standards

- Particle Size Distribution

- Specifies the range and uniformity of particle sizes, critical for applications like filtration and construction.

- Purity

- Defines the minimum percentage of silicon dioxide (SiO₂) and acceptable levels of impurities like iron oxide.

- Grain Shape

- Determines the sphericity and angularity of grains, affecting performance in applications like casting and fracking.

- Bulk Density

- Establishes the weight of silica sand per unit volume, influencing transport and application.

- Chemical Composition

- Ensures the absence of harmful contaminants and meets industry-specific requirements.

How to Ensure Compliance with Silica Sand Standards

- Sourcing from Reliable Suppliers

- Partner with trusted suppliers , who adhere to industry standards.

- Testing and Certification

- Use certified labs to test silica sand for parameters like particle size, purity, and chemical composition.

- Obtain documentation to verify compliance with required standards.

- Regular Quality Checks

- Conduct periodic testing to ensure consistent quality over time.

- Proper Documentation

- Maintain records of testing and certifications to demonstrate compliance.

FAQs About Silica Sand Standards

- Why is particle size important in silica sand standards?

- Particle size affects performance in filtration, construction, and other applications, making it a critical standard parameter.

- What is the minimum purity for industrial silica sand?

- Most applications require silica sand with at least 95% SiO₂, with high-purity grades exceeding 99.5%.

- Can silica sand standards vary by region?

- Yes, standards can vary based on local regulations and industry requirements. Always check region-specific guidelines.

Conclusion

Silica sand standards play a crucial role in ensuring its quality, consistency, and safety across various industries. By adhering to recognized standards like ASTM, ISO, and EN, businesses can optimize performance, reduce risks, and maintain regulatory compliance. Regular testing, reliable sourcing, and thorough documentation are key to meeting these standards.

For more information on sourcing high-quality silica sand that meets industry standards or to learn more about its applications, contact us today or visit our website!