How to Measure Silica Sand: Methods and Importance

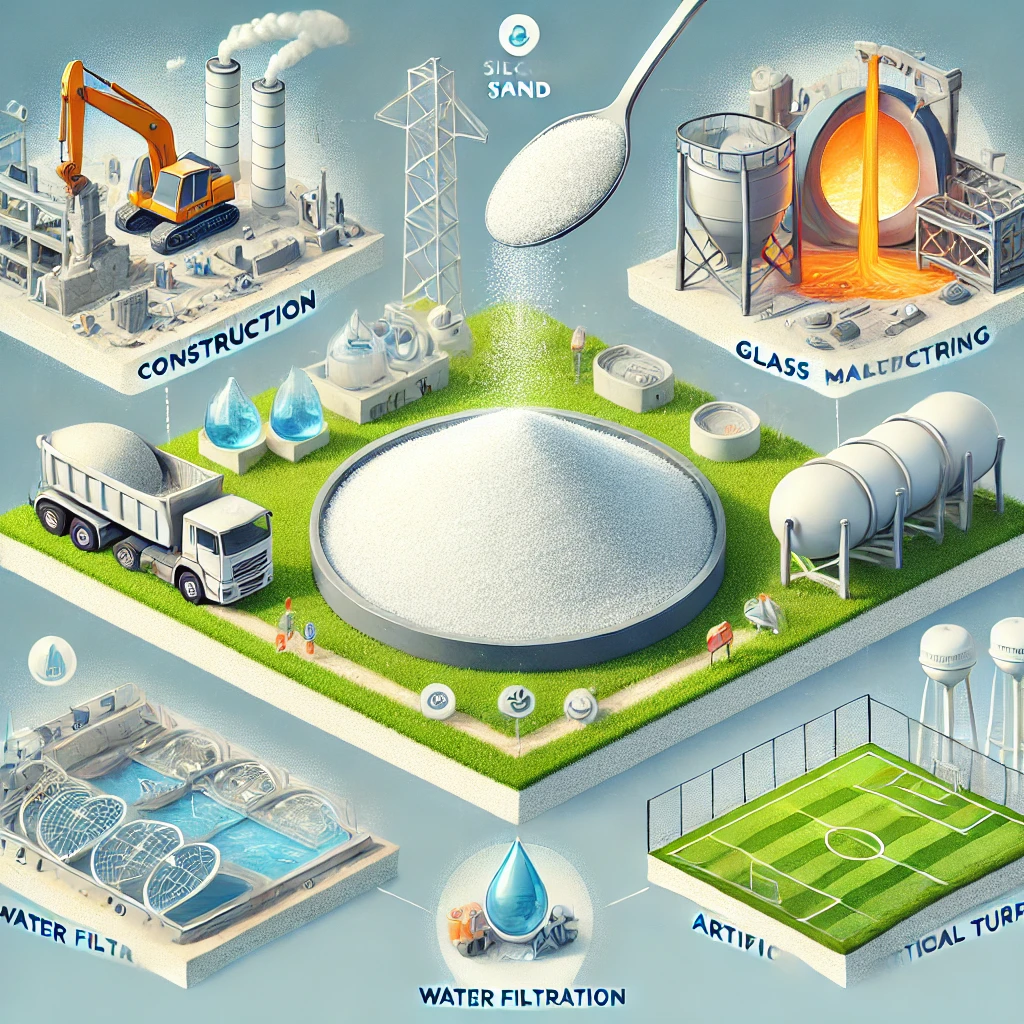

Silica sand is a vital material used across various industries, from glass manufacturing and construction to water filtration and foundry casting. Measuring silica sand ensures that its properties meet specific application requirements. In this article, we’ll explore the methods for measuring silica sand, its critical parameters, and why accurate measurement is essential for industrial success.

Why Measure Silica Sand?

Measuring silica sand allows industries to:

- Ensure the sand meets quality and purity standards.

- Optimize performance in applications like filtration, casting, and construction.

- Avoid costly errors caused by unsuitable sand properties.

Key Parameters to Measure

- Particle Size Distribution

- Importance: Determines the sand’s behavior in filtration, glassmaking, and concrete mixing.

- How to Measure:

- Sieve Analysis:

- Pass the sand through a series of sieves with decreasing mesh sizes.

- Weigh the retained material on each sieve to analyze the particle size distribution.

- Laser Diffraction:

- Use laser diffraction instruments for precise measurement, especially for finer particles.

- Sieve Analysis:

- Purity

- Importance: High-purity silica sand is critical for applications like glass and electronics.

- How to Measure:

- Chemical Analysis:

- Perform X-ray fluorescence (XRF) to identify the composition and measure the percentage of silicon dioxide (SiO₂) and impurities.

- Acid Test:

- Treat sand with acid to reveal the presence of impurities like iron or aluminum.

- Chemical Analysis:

- Grain Shape

- Importance: Affects flowability, compaction, and the end-use performance.

- How to Measure:

- Microscopy: Examine grains under a microscope to evaluate angularity, roundness, and uniformity.

- Image Analysis: Use software to quantify grain shape.

- Bulk Density

- Importance: Influences storage, transport, and application in construction and casting.

- How to Measure:

- Use a calibrated container to measure the mass of a known volume of silica sand.

- Calculate bulk density: Bulk Density=Mass/Volume

- Moisture Content

- Importance: Impacts the weight and usability of silica sand.

- How to Measure:

- Weigh the sand sample, dry it in an oven at 105°C until it reaches a constant weight, and calculate:

- Specific Gravity

- Importance: Determines the density of silica sand relative to water.

- How to Measure:

- Use a pycnometer or hydrometer to compare the weight of the sand to the weight of an equal volume of water.

- Color and Visual Quality

- Importance: Aesthetic and purity indicators, especially for glassmaking.

- How to Measure:

- Visually inspect for uniform color, brightness, and absence of impurities.

Methods of Measurement

- Sieve Analysis for Particle Size

- A widely used method to determine the grain size distribution.

- Requires standard sieves and a mechanical shaker.

- Chemical Analysis for Purity

- Use XRF equipment for detailed compositional analysis.

- Perform acid testing for quick impurity checks.

- Microscopy for Grain Shape

- Optical or scanning electron microscopes help analyze grain morphology.

- Bulk Density Testing

- Calibrated containers and scales are essential for precise bulk density measurements.

- Moisture Testing

- Use oven drying for highly accurate results.

- Advanced Instruments

- Laser diffraction analyzers for fine particle analysis.

- Pycnometers for specific gravity.

Why Accurate Measurement Matters

- Product Quality: Ensures silica sand meets the stringent requirements for specialized applications.

- Cost Savings: Prevents wastage by using correctly measured sand for intended purposes.

- Regulatory Compliance: Adheres to industry standards like ASTM and ISO for quality assurance.

- Enhanced Performance: Guarantees better results in applications like filtration, casting, and glass manufacturing.

FAQs About Measuring Silica Sand

- What is the most critical parameter to measure?

- Particle size and purity are generally the most important, depending on the application.

- Can silica sand be reprocessed to meet requirements?

- Yes, silica sand can be sieved, cleaned, or crushed to achieve desired specifications.

- What tools are needed for measurement?

- Standard sieves, mechanical shakers, XRF analyzers, microscopes, and moisture meters are common tools.

Conclusion

Measuring silica sand is essential for ensuring its quality, purity, and performance across industries. By understanding the key parameters and employing accurate measurement techniques, businesses can optimize their processes, reduce costs, and achieve better results.

For more information on sourcing high-quality silica sand or to explore its applications, visit our website or contact us today!