The Importance of Particle Size in Silica Sand Applications

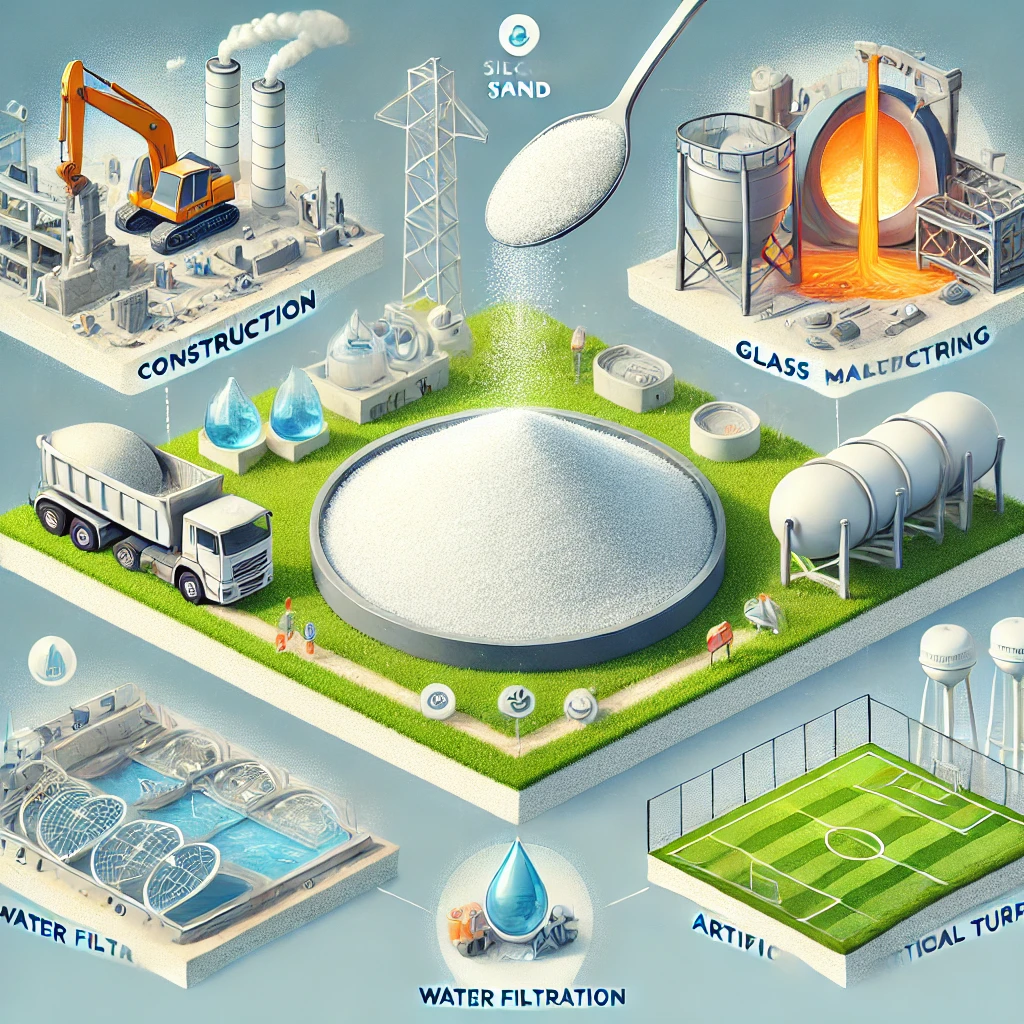

Silica sand, composed primarily of silicon dioxide (SiO₂), is a highly versatile material used across numerous industries. One critical factor determining its performance in various applications is particle size. The size of silica sand particles influences its behavior, efficiency, and effectiveness in processes ranging from glass manufacturing to water filtration and construction. This article delves into why particle size matters, its impact on different industries, and how to choose the right particle size for your needs.

Why Particle Size Matters in Silica Sand

- Performance Optimization

- The particle size of silica sand affects its behavior in specific applications, such as filtration or casting.

- Proper sizing ensures optimal efficiency and desired results.

- Material Properties

- Different particle sizes offer varying surface areas, porosity, and mechanical stability, impacting their effectiveness in different uses.

- Compatibility with Applications

- Fine particles may be better suited for applications requiring smooth finishes, while coarser particles provide strength and stability in structural uses.

Applications and the Role of Particle Size

- Glass Manufacturing

- Fine Particles: Essential for producing clear and uniform glass, as they melt more evenly during the glassmaking process.

- Impact: Uniform particle size prevents imperfections in the final product.

- Construction

- Coarse Particles: Used in concrete, mortar, and cement to enhance strength and reduce shrinkage.

- Fine Particles: Provide smooth finishes in grouting and plastering.

- Water Filtration

- Medium to Coarse Particles: Ensure effective filtration by trapping impurities while maintaining water flow.

- Impact: Proper sizing improves filtration efficiency and longevity of the filtration system.

- Foundry Casting

- Uniform Particle Size: Ensures high-quality molds and cores for casting metals.

- Impact: Reduces defects and enhances precision in casting processes.

- Paints and Coatings

- Fine Particles: Improve adhesion and create smooth, even finishes.

- Impact: Enhances durability and aesthetic appeal.

- Recreational Applications

- Coarse Particles: Preferred for sports surfaces like golf course bunkers and beach volleyball courts.

- Impact: Provides stability and excellent drainage.

Factors to Consider When Selecting Particle Size

- Application Requirements

- Assess the specific needs of your application to determine the ideal particle size.

- Purity Levels

- Ensure the silica sand meets purity standards for your industry.

- Supplier Reliability

- Work with reputable suppliers who offer consistent particle size distributions

- Testing and Grading

- Use sieving and particle size analysis to confirm suitability for the intended purpose.

FAQs About Silica Sand Particle Size

- Why is particle size important in filtration?

- Proper particle size ensures efficient trapping of impurities while maintaining water flow.

- Can silica sand be reprocessed for particle size adjustment?

- Yes, it can be sieved or crushed to achieve the desired size for specific applications.

- What industries benefit the most from tailored particle sizes?

- Glass manufacturing, construction, filtration, and foundry casting are the primary industries that rely on precise particle sizing.

Conclusion

The particle size of silica sand is a critical factor that significantly impacts its performance across various industries. By understanding the role of particle size and selecting the right specifications, businesses can optimize processes, improve product quality, and achieve better results.

For more information on sourcing silica sand with the right particle size for your application or to learn more about its uses, visit our website or contact us today!